Product Description

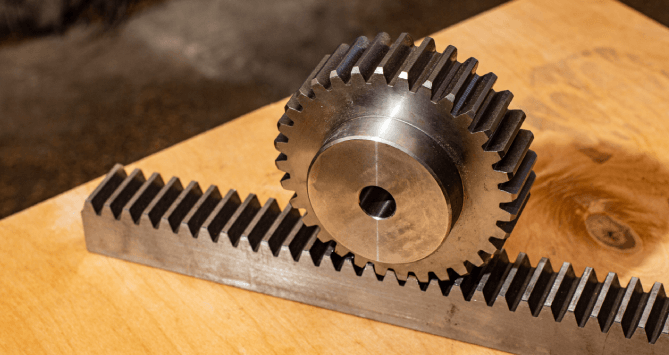

Detailed Photos

Product Parameters

Steel Gear racks:

Our steel Gear Racks are exported in big quantity to Europe,America etc.Our gear racks producedby,CNC machines.Our steel gear racks,cnc gear racks,gear racks M1,racks and pinion steering gears are exported in big quantity to Europe,America,Australia,Brazil,etc.There are standard gear racks available and also special gear racks as per your drawings or sampls.Standards or special gear racks produced by CNC machines.

Note of steel gear racks

1. Material: Carbon steel, stainless steel, aluminium alloy, plastic, brass etc.

2. Module: M1, M1.5, M2, M3, M4, M5, M6, M7, M8 etc.

3. The pressure angle: 20°.

4. Surface treatment: Zinc-plated, Nickle-plated, Black-Oxide, Carburizing, Hardening and tempering,

nitriding, high frequency treatment etc.

5. Production Machines: Gear shaper, hobbing machine, CNC lathe, milling machine, drilling machine,

grinder etc.

6. Heat treatment carburizing and quenching.

7. Surface disposal: forced shot-peening.

Data sheet

| Specification LxWxH(mm) | Material | Module |

| 1005x8x30 |

A3 STEEL C45 STEEL Stainless Steel |

4 |

| 1005x9x30 | 4 | |

| 1005x10x30 | 4 | |

| 1005x11x30 | 4 | |

| 1005x12x30 | 4 | |

| 1002x12x30 | 4 | |

| 1004x12x30 | 4 | |

| 1005x15x30 | 4 | |

| 1005x20x20 | 4 | |

| 1005x22x22 | 4 | |

| 1005x25x25 | 4 | |

| 1005x30x30 | 6 | |

| 1004x8x40 | 5 |

Use:

Our steel gear rack, CNC gear racks, spur gear racks, stainless gear racks, special gear racks, aluminum gear racks, round gear racks, gear and racks, gear rack M4 gear racks, gears rack M1, racks and pinion steering gear are exported in big quantity to Europe, America, Australia, Brasil, South Africa, Russia etc.There is standard gear racks available and also special gear racks as per your drawing or samples. Standards or special gear racks produced by CNC machine.

Our Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling: including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling,

Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack.

8. Other customized Machining Parts according to drawings (OEM) Forging, Casting, Stamping Parts.

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTORY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Standard and Custom |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What types of materials are commonly used for metric gear rack components?

Various materials are commonly used for metric gear rack components, depending on the specific application requirements and desired performance characteristics. Here’s a detailed explanation of the commonly used materials for metric gear rack components:

1. Steel Alloys: Steel alloys are widely used for gear rack components due to their excellent strength, durability, and wear resistance. Different types of steel alloys, such as carbon steel, alloy steel, and stainless steel, are employed based on the specific application needs. Carbon steel is commonly used for general-purpose gear racks, while alloy steel offers enhanced strength and hardness, making it suitable for heavy-duty applications with high loads and demanding operating conditions. Stainless steel is preferred when corrosion resistance is a critical requirement.

2. Cast Iron: Cast iron is another popular material choice for gear rack components. It offers good strength, wear resistance, and damping properties, making it suitable for applications that require noise reduction and shock absorption. Cast iron gear racks are commonly used in machinery and equipment where quiet operation is essential, such as in automotive transmissions and industrial machinery.

3. Non-Ferrous Alloys: Non-ferrous alloys, including bronze, brass, and aluminum, are utilized for gear rack components in certain applications. Bronze is known for its excellent wear resistance, low friction properties, and high load-carrying capacity, making it suitable for heavy-duty applications. Brass, a copper-zinc alloy, offers good corrosion resistance and is often used in gear racks for marine and outdoor applications. Aluminum alloys are lightweight and have good thermal conductivity, making them suitable for applications where weight reduction and heat dissipation are important considerations.

4. Plastics: Certain high-performance plastics, such as polyamide (nylon), acetal (polyoxymethylene), and polyetheretherketone (PEEK), are used for gear rack components in specific applications. Plastics offer advantages such as self-lubrication, low noise generation, and resistance to chemicals and corrosion. They are commonly employed in applications where weight reduction, low friction, and quiet operation are critical, such as in automotive, medical, and food processing equipment.

5. Composite Materials: Composite materials, comprising a combination of fibers (such as carbon fiber or fiberglass) and a resin matrix (such as epoxy or polyester), are utilized in specialized gear rack applications that require high strength, lightweight construction, and resistance to extreme conditions. Composite gear racks offer advantages such as high stiffness-to-weight ratio, excellent fatigue resistance, and resistance to chemicals and temperature variations. They find applications in aerospace, defense, and high-performance machinery.

It is important to note that the selection of materials for gear rack components depends on factors such as the application requirements, load capacity, operating conditions (such as temperature and humidity), desired wear resistance, and cost considerations. Engineers and designers evaluate these factors to choose the most suitable material that balances performance, durability, and cost-effectiveness for the specific application.

In summary, the common materials used for metric gear rack components include steel alloys (carbon steel, alloy steel, stainless steel), cast iron, non-ferrous alloys (bronze, brass, aluminum), plastics (polyamide, acetal, PEEK), and composite materials. Each material offers specific advantages in terms of strength, wear resistance, corrosion resistance, weight reduction, or specialized properties, allowing engineers to select the material that best meets the requirements of the gear rack application.

Can metric gear racks be integrated into robotic and automation equipment?

Yes, metric gear racks can be readily integrated into robotic and automation equipment to enable precise motion control and efficient power transmission. Here’s a detailed explanation of how metric gear racks can be used in robotic and automation applications:

1. Precision Motion Control: Robotic and automation equipment often require precise and controlled motion. Metric gear racks, when combined with compatible mating gears, offer a reliable method for converting rotary motion into linear motion or vice versa. This enables precise positioning, linear actuation, and synchronized movement in robotic arms, linear stages, pick-and-place systems, and other automation equipment. The toothed engagement between the gear rack and the mating gear ensures accurate and repeatable motion control, contributing to the overall precision of the system.

2. Load Handling: Robotic and automation equipment may need to handle varying loads and forces. Metric gear racks are designed to handle high loads, making them suitable for applications where heavy payloads or dynamic forces are involved. The robust construction of gear racks, combined with their ability to distribute loads along the entire length of the rack, ensures efficient transmission of power and reliable load handling capabilities in robotic and automation systems.

3. Compact Design: Space efficiency is often a crucial consideration in robotic and automation equipment design. Metric gear racks offer a compact and efficient solution for linear motion transmission. By utilizing gear racks, linear motion can be achieved without the need for additional components, such as belts, pulleys, or screw mechanisms. This compact design allows for more streamlined and space-saving robotic and automation systems, making gear racks an attractive choice for applications with limited space constraints.

4. Customizability and Versatility: Metric gear racks are available in various sizes, modules, and materials, providing flexibility and customization options for robotic and automation equipment. Engineers can select gear racks with specific dimensions, tooth profiles, and load capacities to match the requirements of the application. This versatility allows for the optimization of gear rack selection based on factors such as load, speed, precision, and environmental conditions, resulting in efficient integration into robotic and automation systems.

5. Compatibility with Other Components: Metric gear racks can be easily integrated with other components commonly used in robotic and automation equipment. They can be combined with motors, encoders, sensors, and control systems to create a comprehensive motion control solution. The compatibility of gear racks with these components facilitates seamless integration and enables precise and coordinated motion control in robotic and automation applications.

6. Reliability and Durability: Robotic and automation systems often operate in demanding and continuous production environments. Metric gear racks are designed to offer high reliability and durability, ensuring long service life and minimal downtime. The use of high-quality materials, precision manufacturing processes, and proper lubrication contribute to the gear racks’ ability to withstand heavy loads, repetitive motion, and challenging operating conditions, making them well-suited for integration into robust robotic and automation equipment.

In summary, metric gear racks can be effectively integrated into robotic and automation equipment to enable precise motion control, efficient power transmission, and reliable operation. Their compatibility with other components, compact design, customizability, and durability make gear racks a suitable choice for a wide range of robotic and automation applications, including pick-and-place systems, assembly lines, CNC machines, material handling systems, and more.

In which industries are metric gear racks commonly used?

Metric gear racks find widespread use in numerous industries where linear motion, motion control, and precision positioning are required. Here’s a detailed explanation of the industries where metric gear racks are commonly used:

1. Manufacturing: Metric gear racks are extensively employed in the manufacturing industry. They are utilized in various machinery and equipment, such as machine tools, conveyor systems, automated assembly lines, and robotic arms. Gear racks enable precise linear motion and positioning, ensuring accurate machining, material handling, and assembly processes. The manufacturing industry encompasses sectors like automotive, aerospace, electronics, consumer goods, and more.

2. Automation and Robotics: Metric gear racks play a crucial role in the automation and robotics industry. They are used in robotic arms, linear actuators, and motion control systems to achieve controlled and precise movement. Gear racks enable robots to perform tasks such as pick-and-place operations, assembly, material handling, and inspection. The automation and robotics industry finds applications in manufacturing, logistics, healthcare, agriculture, and other sectors.

3. Logistics and Material Handling: Metric gear racks are commonly employed in logistics and material handling systems. They facilitate the movement of conveyors, lifts, sorting systems, and automated storage and retrieval systems (AS/RS). Gear racks enable efficient and accurate material flow, aiding in processes like warehousing, distribution, order fulfillment, and package handling. The logistics and material handling industry is vital for supply chain management and encompasses sectors such as e-commerce, retail, and distribution.

4. Printing and Packaging: Metric gear racks are utilized in the printing and packaging industry. They are integrated into printing machinery, such as offset printers, digital printers, and flexographic printers, to enable precise paper movement and registration. Gear racks ensure accurate positioning of the printing substrate, allowing for high-quality prints with tight registration. Additionally, gear racks are used in packaging machinery for controlled material feeding, cutting, and sealing processes.

5. Machine Tools: Metric gear racks are commonly found in the machine tool industry. They are used in milling machines, lathes, drilling machines, and other CNC (computer numerical control) machines. Gear racks provide linear motion along the tool slide, allowing for precise positioning of cutting tools or workpieces. This industry serves various sectors, including metalworking, woodworking, and fabrication.

6. Medical and Healthcare: Metric gear racks have applications in the medical and healthcare industry. They are utilized in medical equipment, diagnostic devices, and laboratory instruments that require precise linear motion and positioning. Gear racks enable controlled movement in equipment such as medical imaging systems, robotic surgery systems, and laboratory automation systems. The medical and healthcare industry encompasses areas like hospitals, clinics, research laboratories, and medical device manufacturing.

7. Scientific Research and Instrumentation: Metric gear racks are used in scientific research and instrumentation applications. They find application in precision equipment, analytical instruments, and scientific devices that require accurate linear motion. Gear racks enable controlled movement in devices such as spectrometers, microscopes, telescopes, and experimental setups. This industry includes research institutions, universities, laboratories, and scientific instrument manufacturers.

8. Automotive and Transportation: Metric gear racks are employed in the automotive and transportation industry. They are utilized in automotive manufacturing processes, including assembly lines, robotic welding systems, and paint booths. Gear racks enable precise linear motion for component positioning and movement control. Additionally, gear racks find application in transportation systems like railway signaling, door mechanisms, and control systems. The automotive and transportation industry involves vehicle manufacturing, transportation infrastructure, and logistics.

9. Energy and Power: Metric gear racks have applications in the energy and power industry. They are used in equipment such as wind turbines, solar tracking systems, and hydroelectric power plants. Gear racks enable controlled movement for optimizing energy capture and conversion. They facilitate the adjustment of rotor blades, solar panels, and other components to maximize energy generation. The energy and power industry encompasses renewable energy, conventional power generation, and utilities.

10. Electronics and Semiconductor: Metric gear racks are employed in the electronics and semiconductor industry. They find application in manufacturing processes such as semiconductor wafer handling, printed circuit board (PCB) assembly, and display panel production. Gear racks enable precise movement and positioning of components, ensuring accuracy and reliability in electronic device manufacturing. This industry includes sectors like consumer electronics, semiconductor fabrication, and electronic component manufacturing.

These are some of the industries where metric gear racks are commonly used. The versatility and reliability of gear racks make them essential components in various applications that require linear motion, motion control, and precision positioning.

editor by Dream 2024-05-06