Product Description

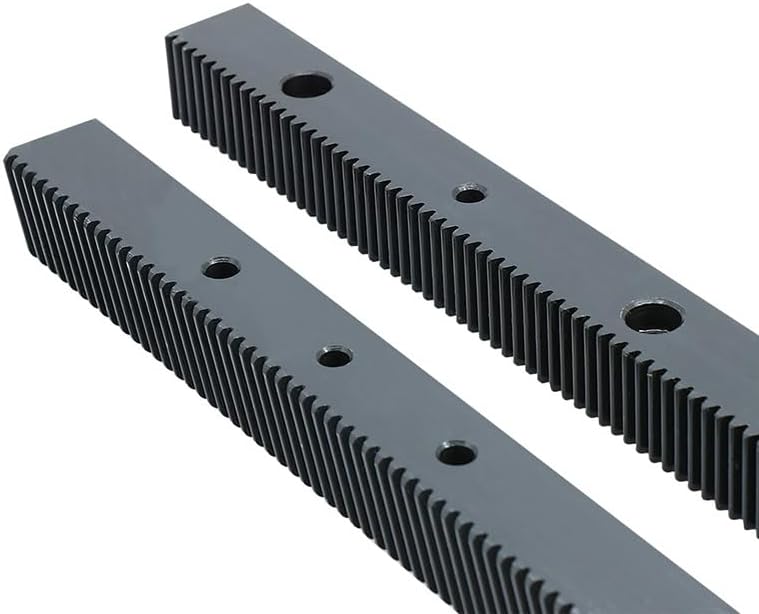

Gear Rack Great quality stainless steel helical Spur POM Plastic and pinion steering metric Ground linear flexible best price manufacturer industrial Gear Rack

Our spur and helical gear racks are welcomed by many customers for its stable high quality and competitive price.

The producing character of EP gear racks.

1. Gear rack length: the longest is 4000mm without joint. It can be jointed to any length.

2. Material: steel C45, stainless steel, high strength steel, copper, aluminium, nylon, plastic, POM etc;

3. Module: 0.3-8 (pitch from 0.942-25.12mm, DP 3.175-85);

4. Quality: stable and high: accumulated tolerance 0.1mm per 1000mm for normal quality;

Accumulated tolerance 0.02mm per 1000mm for 4 sides ground.

Prices for above quality are very competitive for us.

The quality character of EP gear racks:

1. Stable transmission and low noise;

2. Effectively avoid normal tolerance based on high precision;

3. The surfaces can be ground to grade 7 quality, and teeth can be ground to grade 6 quality;

4. The mounting holes can be made as request;

5. The price is competitive even the quality is high.

| Facilities |

Machining center; CNC gear hobbing machine; CNC gear shaper; CNC gear grinding machine; CNC turning machine; CNC milling machine. Y58200 CNC large gear rack shaper, Y58125A gear rack shaper, England gear rack shaper and Russia gear rack shaper, Gleason machine. |

| Material |

More: PA6, PA66, POM, ABS etc. |

| Teeth type |

Spur teeth gear rack; Helical teeth gear rack; Round gear rack; Tube gear rack; Curved gear rack. |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Gear Rack |

|---|---|

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Warranty: | 1.5 Years |

| Processing: | Hobbing |

| Color: | White or as Request |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How do metric gear racks handle different gear ratios?

Metric gear racks are not directly involved in handling different gear ratios. Gear ratios are determined by the combination of gear racks with other gears, such as spur gears, helical gears, or bevel gears. However, metric gear racks play a crucial role in the overall gear system and contribute to achieving the desired gear ratio. Here’s a detailed explanation of how metric gear racks interact with other gears to handle different gear ratios:

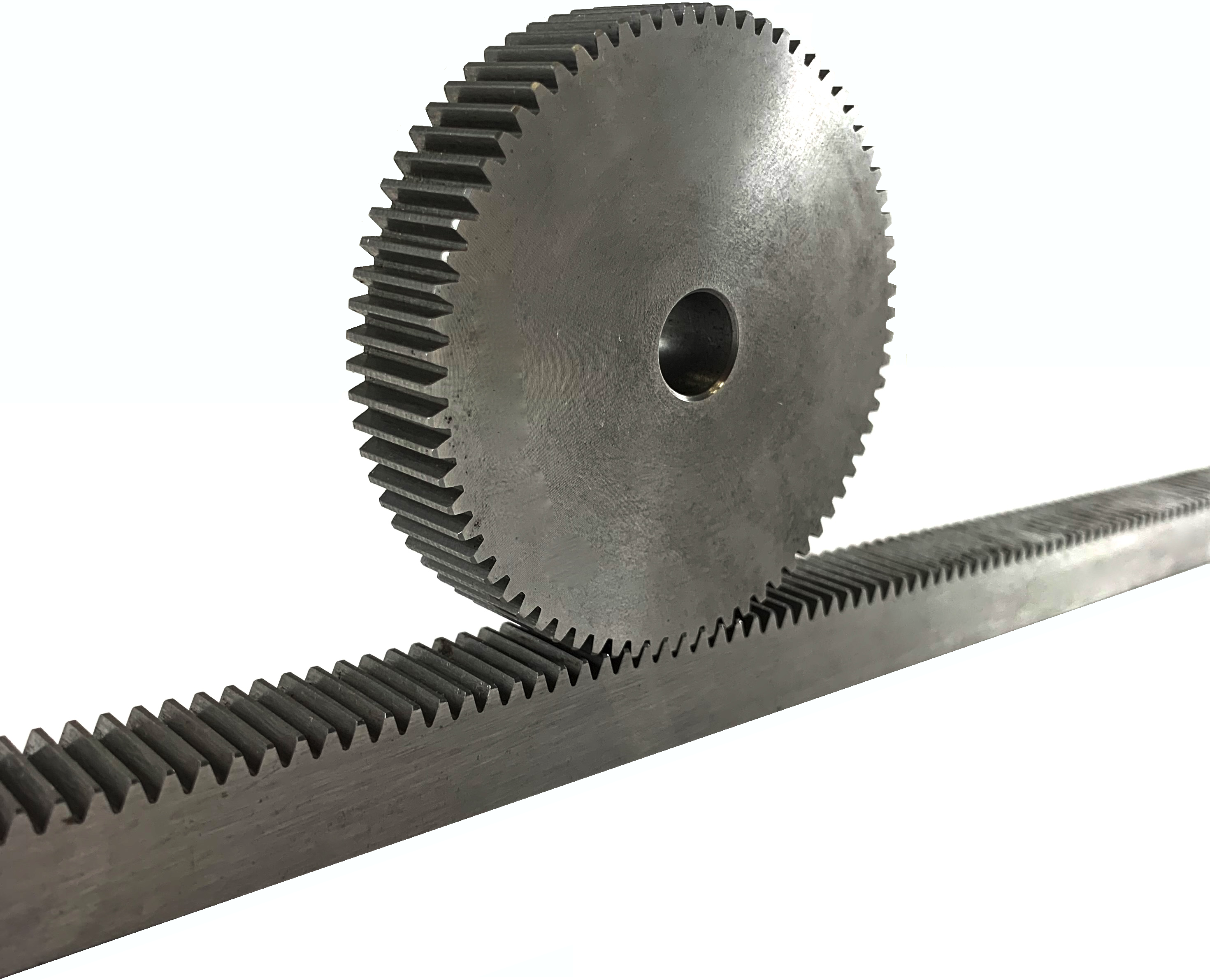

1. Gear Rack Basics: A gear rack is a linear toothed component with straight teeth that meshes with a gear. Unlike traditional gears that rotate, gear racks provide linear motion. They are often used in conjunction with other gears to convert rotational motion into linear motion or vice versa. Gear racks typically have teeth cut along one edge, and these teeth engage with the teeth of the mating gear to transmit power and motion.

2. Spur Gear Systems: One common configuration is to use a spur gear in combination with a gear rack to achieve a specific gear ratio. A spur gear is a cylindrical gear with straight teeth that mesh with the teeth of the gear rack. The gear ratio in this system is determined by the number of teeth on the gear and the length of the gear rack. By selecting gears with different numbers of teeth or using gear racks of varying lengths, different gear ratios can be achieved. The gear ratio is calculated as the ratio of the number of teeth on the gear to the length of the gear rack.

3. Helical Gear Systems: In helical gear systems, helical gears with angled teeth are often used in conjunction with gear racks. Helical gears offer advantages such as smoother operation and increased load-carrying capacity compared to spur gears. The gear ratio in a helical gear system is determined by the number of teeth on the gear and the pitch of the helical gear. The gear rack meshes with the helical gear at a specific angle, and as the gear rotates, it translates the rotational motion into linear motion along the gear rack.

4. Bevel Gear Systems: Bevel gear systems involve the use of bevel gears, which have conical-shaped teeth, to transmit motion between non-parallel shafts. While gear racks are not typically used directly in bevel gear systems, they can be incorporated in conjunction with other gears to achieve specific motion requirements. For example, a bevel gear system may use a combination of bevel gears and gear racks to transmit motion and adjust the gear ratio between intersecting or perpendicular shafts.

It is important to note that the gear ratio achieved in a gear system is not solely determined by the gear rack itself but by the combination of gears and their respective sizes, tooth counts, and profiles. The gear rack’s length or the number of teeth on the rack may influence the overall gear ratio, but it is the interaction between the gear rack and the mating gear that determines the specific ratio achieved.

In summary, metric gear racks are integral components in gear systems that involve the conversion of rotational motion to linear motion or vice versa. They work in conjunction with other gears, such as spur gears, helical gears, or bevel gears, to achieve the desired gear ratio. By selecting gears with different tooth counts and combining them with appropriate gear racks, engineers can design gear systems that handle different gear ratios to meet specific application requirements.

How do metric gear racks handle variations in backlash and precision?

Metric gear racks are designed to minimize variations in backlash and maintain high precision in motion control applications. Here’s a detailed explanation of how metric gear racks handle variations in backlash and precision:

1. Backlash Compensation: Backlash refers to the slight clearance between the teeth of the gear rack and the mating gear. It can introduce positional errors and reduce precision in motion control systems. Metric gear racks can handle variations in backlash by employing various techniques for backlash compensation. One common method is to use a pre-loaded system, where the gear rack and mating gear are designed to exert a slight pressure against each other. This pre-loading minimizes the clearance and reduces the effects of backlash, resulting in improved precision and repeatability in motion control. Additionally, backlash can be further reduced by utilizing gear racks with high tooth engagement ratios, precision manufacturing processes, and tight tolerances, ensuring minimal play between the gear rack and mating gear.

2. Precision Manufacturing: Metric gear racks are manufactured with precision to achieve high levels of accuracy and reduce variations in backlash. The tooth profile of the gear rack is carefully designed and manufactured to ensure smooth and consistent meshing with the mating gear. Advanced machining techniques, such as CNC (Computer Numerical Control) machining and grinding, are used to achieve precise tooth dimensions, tooth profiles, and pitch accuracy. This precision manufacturing process helps minimize variations in backlash and ensures a tight and consistent fit between the gear rack and mating gear, resulting in enhanced precision in motion control applications.

3. Tight Tolerances: Metric gear racks are produced with tight dimensional tolerances to maintain high precision. The manufacturing process ensures that the gear rack’s tooth spacing, pitch, and overall dimensions are within specified tolerances. These tight tolerances minimize variations in backlash and tooth engagement, leading to improved precision and accuracy in motion control. By adhering to strict tolerances, gear racks can reliably transmit motion without excessive play or variations, contributing to precise positioning and consistent motion control performance.

4. Quality Materials: The choice of high-quality materials for metric gear racks is crucial in maintaining precision and reducing backlash variations. Gear racks are commonly made from materials such as steel or stainless steel, which offer excellent strength, durability, and dimensional stability. These materials exhibit minimal expansion or contraction due to temperature changes, ensuring consistent tooth engagement and reducing the effects of thermal variations on backlash and precision. Additionally, the use of high-quality materials helps minimize wear and deformation, preserving the gear rack’s precision over its service life.

5. Regular Maintenance and Inspection: To ensure that metric gear racks continue to handle variations in backlash and maintain precision, regular maintenance and inspection are essential. Periodic lubrication of the gear rack and mating gear reduces friction and wear, optimizing the gear meshing and minimizing backlash variations. Regular inspections allow for the detection of any wear, damage, or misalignment that may affect precision. By addressing maintenance needs promptly and making necessary adjustments or replacements, the gear rack’s performance can be maintained at a high level of precision over time.

6. Application-Specific Optimization: Metric gear racks can be optimized for specific applications to further enhance precision and reduce variations in backlash. Factors such as tooth profile design, material selection, surface treatments, and gear geometry can be tailored to minimize backlash and improve overall precision. By considering the specific requirements and constraints of the application, engineers can optimize gear rack design and configuration to achieve the highest possible precision and reduce variations in backlash.

In summary, metric gear racks handle variations in backlash and maintain high precision through various mechanisms. Backlash compensation techniques, precision manufacturing processes, tight tolerances, quality materials, regular maintenance, and application-specific optimization all contribute to minimizing backlash variations and ensuring high precision in motion control applications. By employing these measures, metric gear racks can reliably provide accurate and repeatable motion, enabling precise positioning and consistent performance in a wide range of applications.

What is a metric gear rack, and how is it used in machinery?

A metric gear rack is a type of gear rack that follows the metric system of measurement. It is used in machinery for various applications that require linear motion and precise positioning. Here’s a detailed explanation of what a metric gear rack is and how it is used in machinery:

A metric gear rack is a linear component with a straight row of teeth that mesh with a mating gear or pinion. The teeth are designed based on the metric module system, where the module represents the size of the gear teeth. The metric system is widely used in many countries and industries, providing a standardized and interchangeable gear rack solution.

Metric gear racks are used in machinery for several purposes:

1. Linear Motion: Metric gear racks are essential for achieving linear motion in machinery. When paired with a mating gear or pinion, the rotation of the gear or pinion is converted into linear motion along the gear rack. This linear motion is utilized in various applications such as conveyor systems, machine tool slides, robotic arms, and linear actuators. Metric gear racks provide a reliable and precise means of achieving linear motion in machinery.

2. Precision Positioning: Metric gear racks are crucial for precise positioning in machinery. The teeth of the gear rack and mating gear or pinion are designed to engage tightly, minimizing backlash and ensuring accurate positioning control. This precision positioning capability is utilized in applications that require accurate placement of components, such as CNC machines, 3D printers, and automated assembly systems. Metric gear racks enable machinery to achieve high levels of positioning accuracy and repeatability.

3. Load Handling: Metric gear racks are designed to handle different loads in machinery. They are manufactured using materials and geometries that provide strength and durability. This allows them to withstand significant loads and forces encountered in various applications. Metric gear racks are employed in machinery that requires the handling and movement of heavy objects, such as industrial robots, material handling systems, and heavy-duty machinery.

4. Customization and Interchangeability: Metric gear racks offer flexibility and interchangeability in machinery design and integration. They are available in various lengths, widths, and module sizes, allowing for customization based on specific machinery requirements. The use of the metric system ensures compatibility and interchangeability between gear racks and mating gears or pinions from different manufacturers. This allows machinery designers and manufacturers to select gear racks that best suit their application needs and easily replace or upgrade components as necessary.

5. Integration with Control Systems: Metric gear racks can be seamlessly integrated into the control systems of machinery, enabling synchronized and coordinated motion. The gear rack system can be connected to motion control algorithms and feedback systems, ensuring accurate and reliable motion control. This integration enables machinery to operate in a coordinated manner, synchronized with other components or processes. Metric gear racks provide the mechanical foundation for achieving precise and coordinated motion control in machinery.

Metric gear racks are widely used in various industries, including manufacturing, automation, robotics, and more. Their adherence to the metric system, combined with their ability to provide linear motion, precise positioning, load handling, customization, and integration capabilities, makes them a versatile and essential component in machinery design and operation.

editor by CX 2023-12-29