Product Description

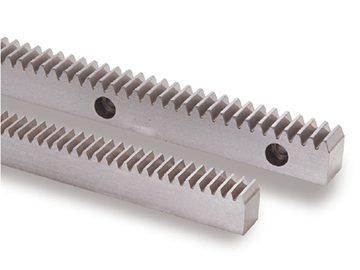

4 or 6 lugs 2-fixing Points Black Customized Heavy Duty Flexible Nylon Sliding Gate Opener Automatic Door Gear Rack for Door opener

|

Product name |

Gear rack |

|||

|

Type |

Helical gear rack,spur gear rack,sliding gate gear rack |

|||

|

Module |

M1,M1.5,M2,M2.5,M3,M4,M5,M6,M8,M10 |

|||

|

Precision |

DIN6,DIN7,DIN8,DIN9 |

|||

|

Surface treatment |

Black oxide,zinc galvanize, heat treatment, |

|||

|

Material |

Carbon steel,stainless steel,brass,pom,nylon,plastic |

|||

|

Process method |

CNC machining, Turning, milling ,drilling, grinding,shaving,shaping,hobbing |

|||

|

Application |

Automotive Parts,Hareware Par,Construction,Machinery, |

|||

|

Standard |

ISO |

|||

Related products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide |

|---|---|

| Warranty: | 1.5 Years |

| Type: | Gear Rack |

| Application: | Excavator |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What types of materials are commonly used for metric gear rack components?

Various materials are commonly used for metric gear rack components, depending on the specific application requirements and desired performance characteristics. Here’s a detailed explanation of the commonly used materials for metric gear rack components:

1. Steel Alloys: Steel alloys are widely used for gear rack components due to their excellent strength, durability, and wear resistance. Different types of steel alloys, such as carbon steel, alloy steel, and stainless steel, are employed based on the specific application needs. Carbon steel is commonly used for general-purpose gear racks, while alloy steel offers enhanced strength and hardness, making it suitable for heavy-duty applications with high loads and demanding operating conditions. Stainless steel is preferred when corrosion resistance is a critical requirement.

2. Cast Iron: Cast iron is another popular material choice for gear rack components. It offers good strength, wear resistance, and damping properties, making it suitable for applications that require noise reduction and shock absorption. Cast iron gear racks are commonly used in machinery and equipment where quiet operation is essential, such as in automotive transmissions and industrial machinery.

3. Non-Ferrous Alloys: Non-ferrous alloys, including bronze, brass, and aluminum, are utilized for gear rack components in certain applications. Bronze is known for its excellent wear resistance, low friction properties, and high load-carrying capacity, making it suitable for heavy-duty applications. Brass, a copper-zinc alloy, offers good corrosion resistance and is often used in gear racks for marine and outdoor applications. Aluminum alloys are lightweight and have good thermal conductivity, making them suitable for applications where weight reduction and heat dissipation are important considerations.

4. Plastics: Certain high-performance plastics, such as polyamide (nylon), acetal (polyoxymethylene), and polyetheretherketone (PEEK), are used for gear rack components in specific applications. Plastics offer advantages such as self-lubrication, low noise generation, and resistance to chemicals and corrosion. They are commonly employed in applications where weight reduction, low friction, and quiet operation are critical, such as in automotive, medical, and food processing equipment.

5. Composite Materials: Composite materials, comprising a combination of fibers (such as carbon fiber or fiberglass) and a resin matrix (such as epoxy or polyester), are utilized in specialized gear rack applications that require high strength, lightweight construction, and resistance to extreme conditions. Composite gear racks offer advantages such as high stiffness-to-weight ratio, excellent fatigue resistance, and resistance to chemicals and temperature variations. They find applications in aerospace, defense, and high-performance machinery.

It is important to note that the selection of materials for gear rack components depends on factors such as the application requirements, load capacity, operating conditions (such as temperature and humidity), desired wear resistance, and cost considerations. Engineers and designers evaluate these factors to choose the most suitable material that balances performance, durability, and cost-effectiveness for the specific application.

In summary, the common materials used for metric gear rack components include steel alloys (carbon steel, alloy steel, stainless steel), cast iron, non-ferrous alloys (bronze, brass, aluminum), plastics (polyamide, acetal, PEEK), and composite materials. Each material offers specific advantages in terms of strength, wear resistance, corrosion resistance, weight reduction, or specialized properties, allowing engineers to select the material that best meets the requirements of the gear rack application.

Can metric gear racks be applied in CNC machining for positioning?

Yes, metric gear racks can be effectively applied in CNC (Computer Numerical Control) machining for precise positioning. Here’s a detailed explanation of how metric gear racks can be used in CNC machining:

1. Precision Positioning: CNC machining requires precise positioning of the cutting tool or workpiece to achieve accurate machining operations. Metric gear racks, when combined with compatible mating gears and a motor, provide a reliable method for converting rotary motion into linear motion. By incorporating a gear rack system into the CNC machine’s axis, such as the X, Y, or Z axis, precise and repeatable linear motion can be achieved. The toothed engagement between the gear rack and the mating gear ensures accurate positioning, enabling the CNC machine to move the cutting tool or workpiece to the desired location with high precision.

2. High Load Capacity: CNC machining often involves handling substantial loads, including the cutting forces exerted on the tool and the weight of the workpiece. Metric gear racks are designed to handle high loads, making them suitable for CNC machining applications. The rack’s robust construction, combined with its ability to distribute loads along the entire length of the rack, ensures efficient power transmission and reliable load handling capabilities. This allows the gear rack system to withstand the forces involved in CNC machining without compromising precision or performance.

3. Longitudinal and Transverse Motion: CNC machines typically have multiple axes of movement to perform various machining operations. Metric gear racks can be applied to both longitudinal (X-axis) and transverse (Y-axis) motion in CNC machining. The gear rack systems can be integrated with linear guides and bearings to provide smooth and precise linear motion along these axes, facilitating accurate positioning of the cutting tool or workpiece in multiple directions. By using gear racks, CNC machines can achieve synchronized and coordinated motion control across different axes, enabling complex machining operations with high accuracy.

4. Backlash Compensation: Backlash, which refers to the slight clearance between the gear rack and mating gear, can introduce positional errors and affect precision in CNC machining. However, metric gear racks can incorporate backlash compensation techniques to minimize the effects of backlash. By utilizing pre-loaded systems or employing gear racks with high tooth engagement ratios, CNC machines can reduce backlash and achieve improved precision in positioning. This ensures that the CNC machine accurately follows the programmed toolpath, resulting in precise machining operations.

5. Compatibility with CNC Systems: Metric gear racks can be seamlessly integrated with CNC control systems and other components commonly used in CNC machines. The gear rack system can be coupled with CNC motors, encoders, and feedback systems to create a comprehensive and synchronized motion control solution. This compatibility allows for precise and coordinated positioning control, ensuring that the CNC machine accurately follows the programmed toolpath and achieves the desired machining results.

6. Customizability and Flexibility: Metric gear racks offer flexibility and customization options to suit different CNC machining applications. They are available in various sizes, modules, and materials, allowing engineers to select gear racks that meet the specific requirements of the CNC machine. Customizable features include tooth profile design, load capacity, and dimensional specifications. This flexibility enables the optimization of gear rack selection based on factors such as load, speed, precision, and environmental conditions, ensuring optimal performance in CNC machining applications.

7. Reliability and Durability: CNC machines are often subjected to continuous operation and demanding machining conditions. Metric gear racks are designed to offer high reliability and durability, ensuring long service life and minimal downtime. The use of high-quality materials, precision manufacturing processes, and proper lubrication contributes to the gear racks’ ability to withstand heavy loads, repetitive motion, and challenging operating conditions. This reliability and durability make gear racks a suitable choice for CNC machining applications.

In summary, metric gear racks can be effectively applied in CNC machining for precise positioning. Their ability to provide precise linear motion, handle high loads, compensate for backlash, compatibility with CNC systems, customizability, and reliability make gear racks a suitable choice for achieving accurate and repeatable motion control in CNC machines. By incorporating gear racks into CNC machining systems, manufacturers can enhance the precision and performance of their machining operations, resulting in high-quality finished products.

What advantages do metric gear racks offer for precise linear motion?

Metric gear racks offer several advantages for achieving precise linear motion. Here’s a detailed explanation of the advantages they provide:

1. High Accuracy: Metric gear racks are designed with teeth that mesh with compatible gears or pinions. This toothed engagement ensures accurate and repeatable linear motion. The teeth on the gear rack and the mating gear or pinion create a positive drive system, eliminating backlash and minimizing positioning errors. This high level of accuracy allows for precise movement and positioning in applications where precision is critical.

2. Precise Positioning: Gear racks enable precise positioning of components or objects along a linear path. By meshing with gears or pinions that convert rotary motion into linear motion, gear racks provide a reliable means of achieving controlled and accurate displacement. This precise positioning capability is essential in applications such as CNC machines, robotic arms, and automated assembly systems, where components need to be placed or moved with high accuracy.

3. Smooth and Stable Motion: Metric gear racks ensure smooth and stable linear motion. The teeth on the gear rack engage with the mating gears or pinions, providing a constant and controlled transfer of motion. This results in consistent and uniform movement without jerks or sudden changes in speed. The smooth and stable motion facilitated by gear racks is crucial for applications that require controlled and reliable movement, such as conveyor systems and linear actuators.

4. Load Capacity: Gear racks offer high load-carrying capacity, making them suitable for applications that involve moving heavy objects or exerting significant forces. The toothed engagement between the gear rack and mating gears or pinions distributes the load evenly along the length of the rack. This load distribution capability allows gear racks to handle substantial loads without compromising the accuracy of linear motion. It is particularly advantageous in industries such as material handling, robotics, and automotive manufacturing.

5. Long Life and Durability: Metric gear racks are designed to withstand continuous use and offer long service life. They are typically made from high-quality materials such as steel or other robust alloys, providing excellent durability and resistance to wear and fatigue. The tooth profile and surface finish of gear racks are engineered to minimize friction and wear during operation. This durability ensures reliable and consistent performance over extended periods, even in demanding environments.

6. Versatility and Compatibility: Metric gear racks offer versatility and compatibility with a wide range of gear systems. They can be used with various types of gears or pinions, allowing for flexibility in system design and integration. Gear racks are available in different sizes, modules, and tooth profiles, making them suitable for diverse applications and requirements. Their compatibility with different gear systems enhances their versatility and ease of implementation in machinery and equipment.

7. Cost-Effective Solution: Metric gear racks offer a cost-effective solution for achieving precise linear motion. Compared to other linear motion mechanisms, such as linear guides or ball screws, gear racks are often more affordable while providing comparable levels of accuracy. Gear racks also have a simpler design and require minimal maintenance, resulting in cost savings over the product’s lifetime. This cost-effectiveness makes gear racks an attractive choice for applications that require precise linear motion within budget constraints.

These advantages make metric gear racks highly suitable for applications that demand precise linear motion, such as CNC machines, robotics, automation systems, and material handling equipment. The combination of accuracy, positioning capability, load capacity, durability, and cost-effectiveness makes gear racks a reliable and efficient solution for achieving precise linear motion in various industries.

editor by Dream 2024-04-29