Product Description

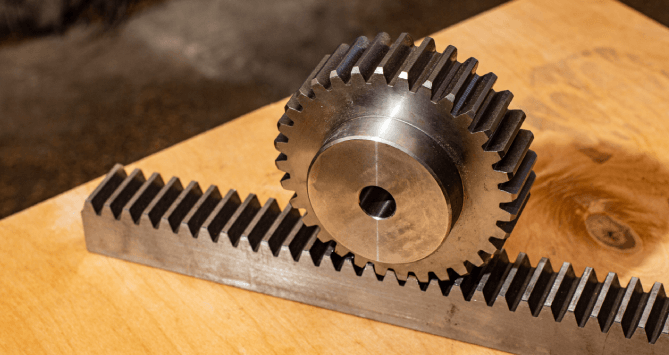

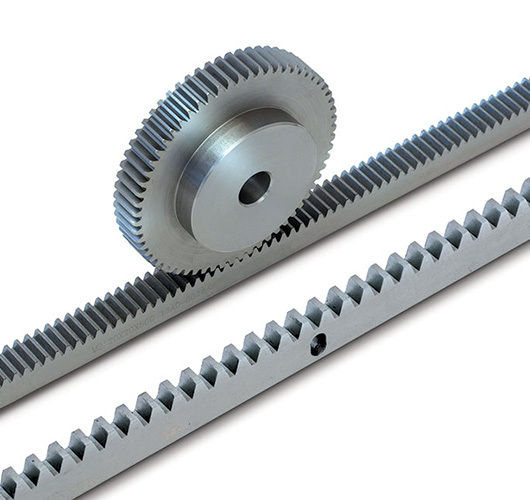

linear motion CNC machine Helical Tooth Automatic Opening Gate Accessory Gate Nylon Plastic Gear Rack for Machine Tool Industry

|

Product name |

Gear rack |

|||

|

Type |

Helical gear rack,spur gear rack,sliding gate gear rack |

|||

|

Module |

M1,M1.5,M2,M2.5,M3,M4,M5,M6,M8,M10 |

|||

|

Precision |

DIN6,DIN7,DIN8,DIN9 |

|||

|

Surface treatment |

Black oxide,zinc galvanize, heat treatment, |

|||

|

Material |

Carbon steel,stainless steel,brass,pom,nylon,plastic |

|||

|

Process method |

CNC machining, Turning, milling ,drilling, grinding,shaving,shaping,hobbing |

|||

|

Application |

Automotive Parts,Hareware Par,Construction,Machinery, |

|||

|

Standard |

ISO |

|||

Related products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide |

|---|---|

| Warranty: | 1.5 Years |

| Type: | Gear Rack |

| Application: | Excavator |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can metric gear racks withstand variations in environmental conditions?

Metric gear racks are designed to withstand variations in environmental conditions to a certain extent. Here’s a detailed explanation of the factors that affect the ability of metric gear racks to withstand environmental conditions:

1. Material Selection: The choice of material for the gear rack is an important consideration when it comes to environmental resistance. Different materials offer varying levels of corrosion resistance, temperature tolerance, and resistance to chemicals or other environmental factors. For example, stainless steel is known for its excellent corrosion resistance, making it suitable for applications exposed to moisture or harsh chemicals. Similarly, certain plastics or composite materials may offer better resistance to specific environmental conditions compared to metals.

2. Coatings and Surface Treatments: Applying specialized coatings or surface treatments can enhance the environmental resistance of gear racks. These coatings can provide protection against corrosion, wear, or chemical attack. Common coatings include zinc plating, nickel plating, or various types of paints or polymer coatings. Surface treatments such as nitriding or carburizing can improve the hardness and wear resistance of the gear rack, making it more resilient to environmental factors.

3. Sealing and Enclosure: In certain applications, gear racks may be enclosed or sealed to protect them from environmental conditions. This can involve using protective covers, seals, or gaskets to prevent the ingress of moisture, dust, or other contaminants. Sealing and enclosure methods help to maintain the integrity of the gear rack and minimize the impact of environmental variations.

4. Temperature Variation: Metric gear racks are designed to operate within specified temperature ranges. The material selection and thermal treatment of the gear rack components play a crucial role in determining their ability to withstand temperature variations. For example, steel alloys are known for their good thermal conductivity and can handle a wide range of temperatures. However, extreme temperature variations, especially rapid changes, can still affect the dimensional stability and performance of gear racks, necessitating appropriate design considerations.

5. Humidity and Moisture: Gear racks exposed to high humidity or moisture levels can be susceptible to corrosion and accelerated wear. The material selection, coatings, and sealing methods are crucial in protecting the gear rack from moisture-related issues. Stainless steel or corrosion-resistant coatings can help mitigate the effects of moisture, but regular maintenance and proper lubrication are also important to ensure the gear rack’s longevity in such conditions.

6. Chemical Exposure: In certain applications, gear racks may come into contact with chemicals or corrosive substances. The resistance of the gear rack to specific chemicals depends on the material composition and surface treatment. It is essential to select materials that are compatible with the chemicals present in the environment and to consider appropriate coatings or protective measures to prevent chemical attack or degradation.

7. Outdoor and Harsh Environments: Gear racks used in outdoor or harsh environments, such as construction equipment or agricultural machinery, may be exposed to additional challenges. These can include exposure to UV radiation, extreme temperatures, abrasive particles, or heavy vibrations. In such cases, materials with good weather resistance, impact resistance, and wear resistance are preferred. Additionally, effective sealing, periodic maintenance, and suitable lubrication are essential to ensure the gear rack’s performance and longevity.

While metric gear racks are designed to withstand variations in environmental conditions, it is important to note that their performance and longevity can be influenced by the severity and duration of exposure to these conditions. Regular inspection, maintenance, and adherence to manufacturer guidelines are crucial to ensure the gear rack’s optimal performance and reliability in specific environmental conditions.

In summary, the ability of metric gear racks to withstand variations in environmental conditions depends on factors such as material selection, coatings and surface treatments, sealing and enclosure methods, temperature variation, humidity and moisture resistance, chemical exposure, and the specific application requirements. By considering these factors and implementing appropriate design measures, engineers can enhance the gear rack’s resistance to environmental variations and ensure its reliable operation over the intended service life.

How do metric gear racks contribute to efficient power transmission?

Metric gear racks play a significant role in enabling efficient power transmission in various mechanical systems. Here’s a detailed explanation of how metric gear racks contribute to efficient power transmission:

1. Direct and Positive Power Transfer: Gear racks provide a direct and positive power transfer mechanism. When meshed with a mating gear, such as a spur gear or a helical gear, the teeth of the gear rack engage with the teeth of the gear, creating a mechanical linkage. This direct engagement ensures a positive power transfer without slippage or energy loss, resulting in efficient power transmission from the driving gear to the gear rack.

2. High Load-Carrying Capacity: Gear racks are designed to handle high loads and transmit power efficiently. The teeth of the gear rack distribute the load along the entire length of the rack, allowing for increased load-carrying capacity compared to other types of power transmission components. This high load-carrying capacity ensures efficient power transmission without excessive wear or deformation, even under heavy loads or dynamic conditions.

3. Efficient Force Distribution: The tooth profile of the gear rack is carefully designed to ensure uniform force distribution along the teeth engagement. This uniform force distribution minimizes localized stress concentrations and allows for efficient power transmission across the entire gear rack. It helps prevent tooth breakage, excessive wear, and premature failure, resulting in improved power transmission efficiency and longevity.

4. Precision and Accuracy: Metric gear racks are manufactured to precise dimensions and tooth profiles, ensuring accurate and repeatable motion transmission. The precision of the teeth engagement between the gear rack and the mating gear contributes to efficient power transmission by minimizing backlash, vibrations, and energy losses associated with misalignment or inconsistent meshing. This precision allows for smooth and reliable power transfer, particularly in applications that require high positional accuracy or synchronized motion.

5. Customizability and Versatility: Metric gear racks offer flexibility in design and customization, allowing engineers to optimize power transmission efficiency for specific applications. They are available in various sizes, modules, and materials, enabling the selection of the most suitable gear rack for a given application’s requirements. The ability to choose the appropriate gear rack ensures efficient power transmission by matching the rack’s specifications to the load, speed, and environmental conditions of the system.

6. Efficient Lubrication and Maintenance: Proper lubrication is crucial for efficient power transmission and the longevity of gear racks. Adequate lubrication reduces friction and wear between the gear rack and the mating gear, resulting in improved power transmission efficiency. Additionally, gear racks are designed for ease of maintenance, allowing for periodic inspection, lubrication, and replacement, if necessary. Regular maintenance helps to ensure optimal performance and efficient power transmission over the gear rack’s service life.

7. Application-Specific Optimization: Metric gear racks can be optimized for specific applications to further enhance power transmission efficiency. Factors such as tooth profile design, material selection, surface treatments, and gear geometry can be tailored to minimize friction, reduce noise, increase wear resistance, and improve overall efficiency. By considering the specific requirements and constraints of the application, engineers can optimize gear rack design and configuration to achieve the highest possible power transmission efficiency.

In summary, metric gear racks contribute to efficient power transmission through direct and positive power transfer, high load-carrying capacity, efficient force distribution, precision and accuracy, customizability and versatility, proper lubrication and maintenance, and application-specific optimization. These factors ensure reliable and efficient power transmission in various mechanical systems, enabling the effective transfer of power from the driving gear to the gear rack while minimizing energy losses, wear, and misalignment-related issues.

How do metric gear racks handle variations in load capacity and speed?

Metric gear racks are designed to handle variations in load capacity and speed effectively. Here’s a detailed explanation of how they address these variations:

Metric gear racks accommodate variations in load capacity and speed through the following mechanisms:

1. Selection of Gear Rack Material: The choice of material for the gear rack plays a crucial role in determining its load capacity and speed handling capabilities. Gear racks are typically made from high-strength materials like steel or other durable alloys. These materials offer excellent load-bearing capacity and can withstand high forces without deformation or failure. The selection of the appropriate material ensures that the gear rack can handle varying loads without compromising its structural integrity or performance.

2. Proper Gear Rack Sizing: The size and dimensions of the gear rack are selected based on the anticipated load and speed requirements of the application. Larger gear racks with more substantial cross-sectional dimensions and larger teeth are capable of handling higher loads. Smaller gear racks are suitable for lighter loads. Proper sizing ensures that the gear rack can withstand the expected load capacity while maintaining the required speed and accuracy. Engineering calculations and analysis are often performed to determine the optimal size and dimensions of the gear rack for a given application.

3. Load Distribution: Gear racks distribute the applied load along their length, which helps in handling variations in load capacity. The toothed engagement between the gear rack and mating gears or pinions ensures that the load is evenly distributed across the entire length of the rack. This load distribution mechanism prevents localized stress concentration and minimizes the risk of failure or deformation in specific areas. By distributing the load, gear racks can handle variations in load capacity and maintain consistent performance throughout their length.

4. Lubrication and Maintenance: Proper lubrication and maintenance of gear racks are essential for ensuring their optimal performance under varying load and speed conditions. Lubrication helps reduce friction and wear between the gear rack teeth and the mating gears or pinions. Adequate lubrication minimizes heat generation, reduces the risk of premature wear, and maintains the overall efficiency of the gear system. Regular inspection and maintenance of gear racks, including cleaning, lubrication, and replacement of worn components, help extend their service life and ensure reliable operation under varying load and speed requirements.

5. System Design and Integration: The overall design and integration of the gear rack system play a vital role in handling variations in load capacity and speed. Proper system design includes selecting compatible gears or pinions, ensuring proper alignment, and considering factors such as torque requirements, backlash, and speed ratios. By designing the gear rack system appropriately, engineers can optimize its performance and ensure that it can handle variations in load capacity and speed effectively.

It is important to note that while gear racks can handle variations in load capacity and speed, there are limits to their capabilities. Exceeding the recommended load capacity or operating at excessively high speeds can lead to premature wear, increased backlash, reduced accuracy, and potential system failure. Therefore, it is crucial to carefully consider the specific load and speed requirements of the application and select gear racks that are suitable for the anticipated operating conditions.

In summary, metric gear racks handle variations in load capacity and speed through the selection of appropriate materials, proper sizing, load distribution, lubrication and maintenance, and thoughtful system design and integration. By considering these factors, gear racks can effectively handle varying load and speed requirements while maintaining accurate and reliable linear motion.

editor by Dream 2024-05-07

China supplier Factory Directly Supply for Machinery Industry Elevator Straight Spur Gear Rack spiral bevel gear

Product Description

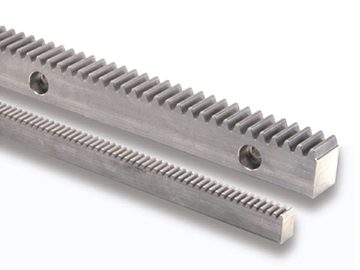

Detailed Photos

Product Parameters

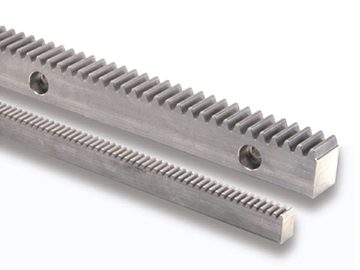

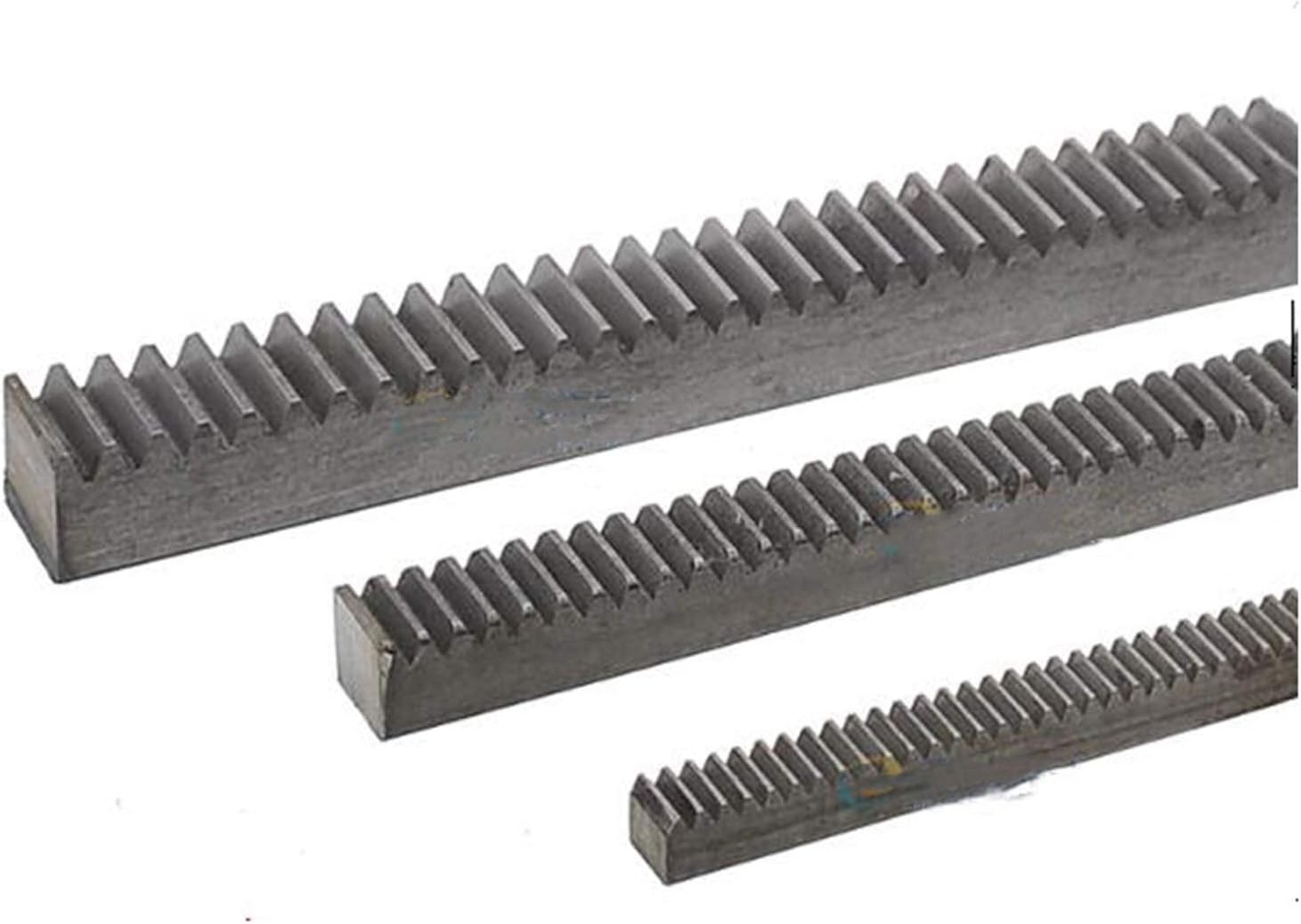

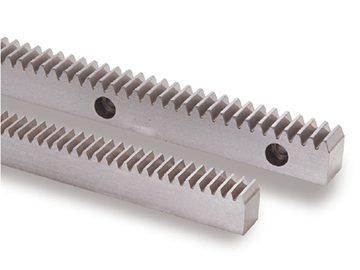

Steel Gear racks:

Our steel Gear Racks are exported in big quantity to Europe,America etc.Our gear racks producedby,CNC machines.Our steel gear racks,cnc gear racks,gear racks M1,racks and pinion steering gears are exported in big quantity to Europe,America,Australia,Brazil,etc.There are standard gear racks available and also special gear racks as per your drawings or sampls.Standards or special gear racks produced by CNC machines.

Note of steel gear racks

1. Material: Carbon steel, stainless steel, aluminium alloy, plastic, brass etc.

2. Module: M1, M1.5, M2, M3, M4, M5, M6, M7, M8 etc.

3. The pressure angle: 20°.

4. Surface treatment: Zinc-plated, Nickle-plated, Black-Oxide, Carburizing, Hardening and tempering,

nitriding, high frequency treatment etc.

5. Production Machines: Gear shaper, hobbing machine, CNC lathe, milling machine, drilling machine,

grinder etc.

6. Heat treatment carburizing and quenching.

7. Surface disposal: forced shot-peening.

Data sheet

| Specification LxWxH(mm) | Material | Module |

| 1005x8x30 |

A3 STEEL C45 STEEL Stainless Steel |

4 |

| 1005x9x30 | 4 | |

| 1005x10x30 | 4 | |

| 1005x11x30 | 4 | |

| 1005x12x30 | 4 | |

| 1002x12x30 | 4 | |

| 1004x12x30 | 4 | |

| 1005x15x30 | 4 | |

| 1005x20x20 | 4 | |

| 1005x22x22 | 4 | |

| 1005x25x25 | 4 | |

| 1005x30x30 | 6 | |

| 1004x8x40 | 5 |

Use:

Our steel gear rack, CNC gear racks, spur gear racks, stainless gear racks, special gear racks, aluminum gear racks, round gear racks, gear and racks, gear rack M4 gear racks, gears rack M1, racks and pinion steering gear are exported in big quantity to Europe, America, Australia, Brasil, South Africa, Russia etc.There is standard gear racks available and also special gear racks as per your drawing or samples. Standards or special gear racks produced by CNC machine.

Our Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling: including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling,

Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack.

8. Other customized Machining Parts according to drawings (OEM) Forging, Casting, Stamping Parts.

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTORY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Standard and Custom |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What types of materials are commonly used for metric gear rack components?

Various materials are commonly used for metric gear rack components, depending on the specific application requirements and desired performance characteristics. Here’s a detailed explanation of the commonly used materials for metric gear rack components:

1. Steel Alloys: Steel alloys are widely used for gear rack components due to their excellent strength, durability, and wear resistance. Different types of steel alloys, such as carbon steel, alloy steel, and stainless steel, are employed based on the specific application needs. Carbon steel is commonly used for general-purpose gear racks, while alloy steel offers enhanced strength and hardness, making it suitable for heavy-duty applications with high loads and demanding operating conditions. Stainless steel is preferred when corrosion resistance is a critical requirement.

2. Cast Iron: Cast iron is another popular material choice for gear rack components. It offers good strength, wear resistance, and damping properties, making it suitable for applications that require noise reduction and shock absorption. Cast iron gear racks are commonly used in machinery and equipment where quiet operation is essential, such as in automotive transmissions and industrial machinery.

3. Non-Ferrous Alloys: Non-ferrous alloys, including bronze, brass, and aluminum, are utilized for gear rack components in certain applications. Bronze is known for its excellent wear resistance, low friction properties, and high load-carrying capacity, making it suitable for heavy-duty applications. Brass, a copper-zinc alloy, offers good corrosion resistance and is often used in gear racks for marine and outdoor applications. Aluminum alloys are lightweight and have good thermal conductivity, making them suitable for applications where weight reduction and heat dissipation are important considerations.

4. Plastics: Certain high-performance plastics, such as polyamide (nylon), acetal (polyoxymethylene), and polyetheretherketone (PEEK), are used for gear rack components in specific applications. Plastics offer advantages such as self-lubrication, low noise generation, and resistance to chemicals and corrosion. They are commonly employed in applications where weight reduction, low friction, and quiet operation are critical, such as in automotive, medical, and food processing equipment.

5. Composite Materials: Composite materials, comprising a combination of fibers (such as carbon fiber or fiberglass) and a resin matrix (such as epoxy or polyester), are utilized in specialized gear rack applications that require high strength, lightweight construction, and resistance to extreme conditions. Composite gear racks offer advantages such as high stiffness-to-weight ratio, excellent fatigue resistance, and resistance to chemicals and temperature variations. They find applications in aerospace, defense, and high-performance machinery.

It is important to note that the selection of materials for gear rack components depends on factors such as the application requirements, load capacity, operating conditions (such as temperature and humidity), desired wear resistance, and cost considerations. Engineers and designers evaluate these factors to choose the most suitable material that balances performance, durability, and cost-effectiveness for the specific application.

In summary, the common materials used for metric gear rack components include steel alloys (carbon steel, alloy steel, stainless steel), cast iron, non-ferrous alloys (bronze, brass, aluminum), plastics (polyamide, acetal, PEEK), and composite materials. Each material offers specific advantages in terms of strength, wear resistance, corrosion resistance, weight reduction, or specialized properties, allowing engineers to select the material that best meets the requirements of the gear rack application.

Can metric gear racks be integrated into robotic and automation equipment?

Yes, metric gear racks can be readily integrated into robotic and automation equipment to enable precise motion control and efficient power transmission. Here’s a detailed explanation of how metric gear racks can be used in robotic and automation applications:

1. Precision Motion Control: Robotic and automation equipment often require precise and controlled motion. Metric gear racks, when combined with compatible mating gears, offer a reliable method for converting rotary motion into linear motion or vice versa. This enables precise positioning, linear actuation, and synchronized movement in robotic arms, linear stages, pick-and-place systems, and other automation equipment. The toothed engagement between the gear rack and the mating gear ensures accurate and repeatable motion control, contributing to the overall precision of the system.

2. Load Handling: Robotic and automation equipment may need to handle varying loads and forces. Metric gear racks are designed to handle high loads, making them suitable for applications where heavy payloads or dynamic forces are involved. The robust construction of gear racks, combined with their ability to distribute loads along the entire length of the rack, ensures efficient transmission of power and reliable load handling capabilities in robotic and automation systems.

3. Compact Design: Space efficiency is often a crucial consideration in robotic and automation equipment design. Metric gear racks offer a compact and efficient solution for linear motion transmission. By utilizing gear racks, linear motion can be achieved without the need for additional components, such as belts, pulleys, or screw mechanisms. This compact design allows for more streamlined and space-saving robotic and automation systems, making gear racks an attractive choice for applications with limited space constraints.

4. Customizability and Versatility: Metric gear racks are available in various sizes, modules, and materials, providing flexibility and customization options for robotic and automation equipment. Engineers can select gear racks with specific dimensions, tooth profiles, and load capacities to match the requirements of the application. This versatility allows for the optimization of gear rack selection based on factors such as load, speed, precision, and environmental conditions, resulting in efficient integration into robotic and automation systems.

5. Compatibility with Other Components: Metric gear racks can be easily integrated with other components commonly used in robotic and automation equipment. They can be combined with motors, encoders, sensors, and control systems to create a comprehensive motion control solution. The compatibility of gear racks with these components facilitates seamless integration and enables precise and coordinated motion control in robotic and automation applications.

6. Reliability and Durability: Robotic and automation systems often operate in demanding and continuous production environments. Metric gear racks are designed to offer high reliability and durability, ensuring long service life and minimal downtime. The use of high-quality materials, precision manufacturing processes, and proper lubrication contribute to the gear racks’ ability to withstand heavy loads, repetitive motion, and challenging operating conditions, making them well-suited for integration into robust robotic and automation equipment.

In summary, metric gear racks can be effectively integrated into robotic and automation equipment to enable precise motion control, efficient power transmission, and reliable operation. Their compatibility with other components, compact design, customizability, and durability make gear racks a suitable choice for a wide range of robotic and automation applications, including pick-and-place systems, assembly lines, CNC machines, material handling systems, and more.

In which industries are metric gear racks commonly used?

Metric gear racks find widespread use in numerous industries where linear motion, motion control, and precision positioning are required. Here’s a detailed explanation of the industries where metric gear racks are commonly used:

1. Manufacturing: Metric gear racks are extensively employed in the manufacturing industry. They are utilized in various machinery and equipment, such as machine tools, conveyor systems, automated assembly lines, and robotic arms. Gear racks enable precise linear motion and positioning, ensuring accurate machining, material handling, and assembly processes. The manufacturing industry encompasses sectors like automotive, aerospace, electronics, consumer goods, and more.

2. Automation and Robotics: Metric gear racks play a crucial role in the automation and robotics industry. They are used in robotic arms, linear actuators, and motion control systems to achieve controlled and precise movement. Gear racks enable robots to perform tasks such as pick-and-place operations, assembly, material handling, and inspection. The automation and robotics industry finds applications in manufacturing, logistics, healthcare, agriculture, and other sectors.

3. Logistics and Material Handling: Metric gear racks are commonly employed in logistics and material handling systems. They facilitate the movement of conveyors, lifts, sorting systems, and automated storage and retrieval systems (AS/RS). Gear racks enable efficient and accurate material flow, aiding in processes like warehousing, distribution, order fulfillment, and package handling. The logistics and material handling industry is vital for supply chain management and encompasses sectors such as e-commerce, retail, and distribution.

4. Printing and Packaging: Metric gear racks are utilized in the printing and packaging industry. They are integrated into printing machinery, such as offset printers, digital printers, and flexographic printers, to enable precise paper movement and registration. Gear racks ensure accurate positioning of the printing substrate, allowing for high-quality prints with tight registration. Additionally, gear racks are used in packaging machinery for controlled material feeding, cutting, and sealing processes.

5. Machine Tools: Metric gear racks are commonly found in the machine tool industry. They are used in milling machines, lathes, drilling machines, and other CNC (computer numerical control) machines. Gear racks provide linear motion along the tool slide, allowing for precise positioning of cutting tools or workpieces. This industry serves various sectors, including metalworking, woodworking, and fabrication.

6. Medical and Healthcare: Metric gear racks have applications in the medical and healthcare industry. They are utilized in medical equipment, diagnostic devices, and laboratory instruments that require precise linear motion and positioning. Gear racks enable controlled movement in equipment such as medical imaging systems, robotic surgery systems, and laboratory automation systems. The medical and healthcare industry encompasses areas like hospitals, clinics, research laboratories, and medical device manufacturing.

7. Scientific Research and Instrumentation: Metric gear racks are used in scientific research and instrumentation applications. They find application in precision equipment, analytical instruments, and scientific devices that require accurate linear motion. Gear racks enable controlled movement in devices such as spectrometers, microscopes, telescopes, and experimental setups. This industry includes research institutions, universities, laboratories, and scientific instrument manufacturers.

8. Automotive and Transportation: Metric gear racks are employed in the automotive and transportation industry. They are utilized in automotive manufacturing processes, including assembly lines, robotic welding systems, and paint booths. Gear racks enable precise linear motion for component positioning and movement control. Additionally, gear racks find application in transportation systems like railway signaling, door mechanisms, and control systems. The automotive and transportation industry involves vehicle manufacturing, transportation infrastructure, and logistics.

9. Energy and Power: Metric gear racks have applications in the energy and power industry. They are used in equipment such as wind turbines, solar tracking systems, and hydroelectric power plants. Gear racks enable controlled movement for optimizing energy capture and conversion. They facilitate the adjustment of rotor blades, solar panels, and other components to maximize energy generation. The energy and power industry encompasses renewable energy, conventional power generation, and utilities.

10. Electronics and Semiconductor: Metric gear racks are employed in the electronics and semiconductor industry. They find application in manufacturing processes such as semiconductor wafer handling, printed circuit board (PCB) assembly, and display panel production. Gear racks enable precise movement and positioning of components, ensuring accuracy and reliability in electronic device manufacturing. This industry includes sectors like consumer electronics, semiconductor fabrication, and electronic component manufacturing.

These are some of the industries where metric gear racks are commonly used. The versatility and reliability of gear racks make them essential components in various applications that require linear motion, motion control, and precision positioning.

editor by Dream 2024-05-06

China Good quality Flexible Superior 40cr Steel M4 Roller Conveyor Industrial Engraving Spur Helical Gear Rack for Material Handling Industry bevel gear set

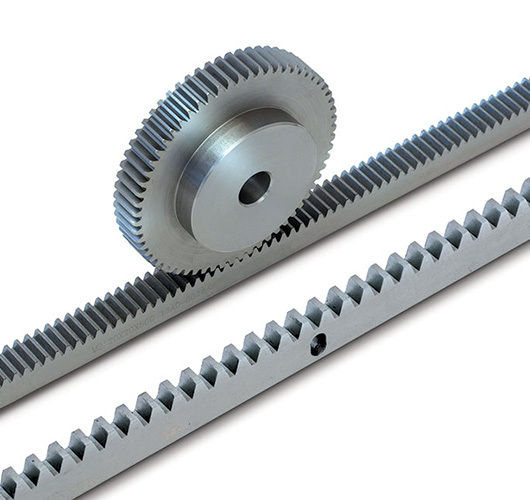

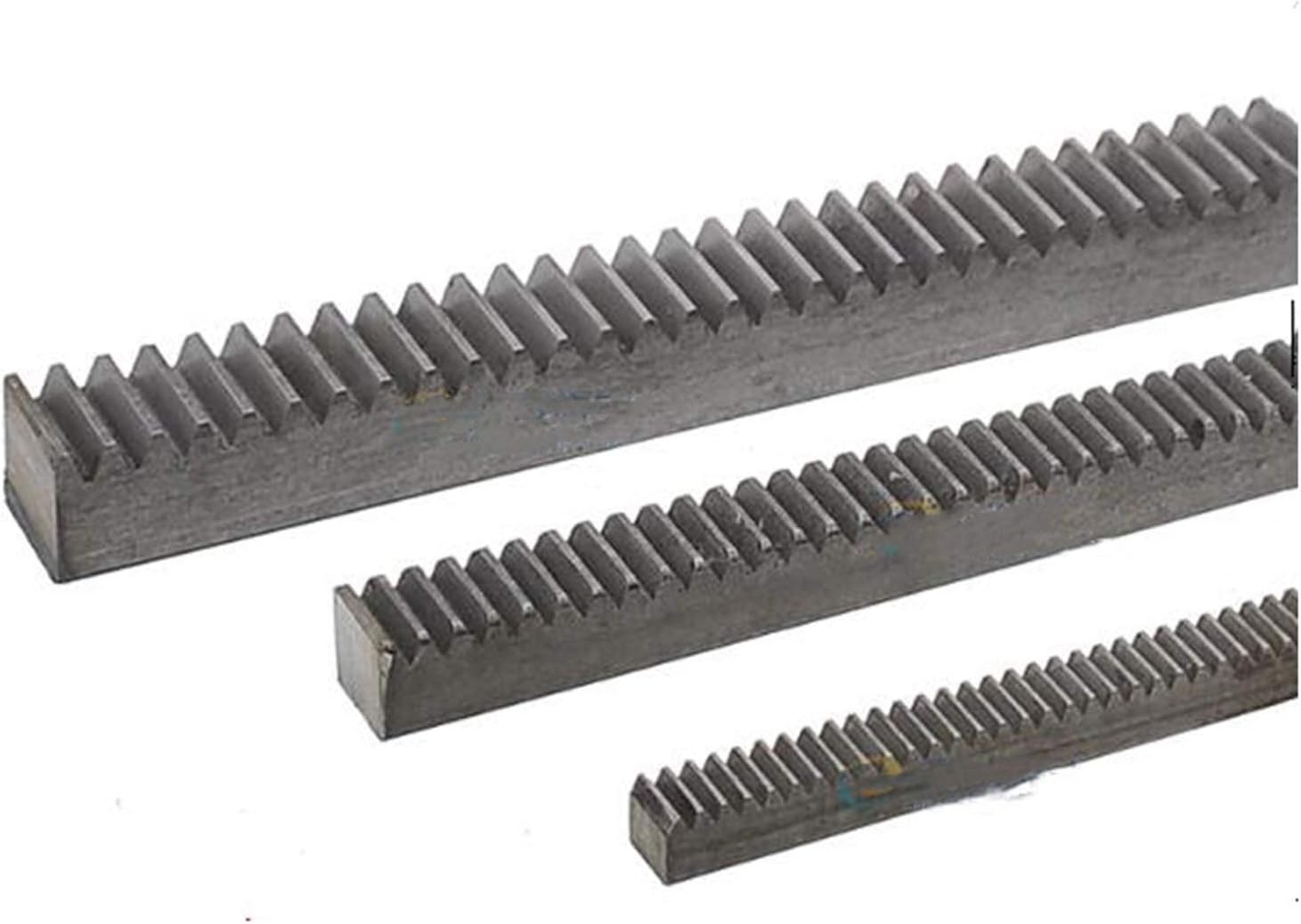

Product Description

Flexible superior 40Cr steel m4 Roller Conveyor industrial engraving spur helical gear rack for Material Handling Industry

|

Product name |

Gear rack |

|||

|

Type |

Helical gear rack,spur gear rack,sliding gate gear rack |

|||

|

Module |

M1,M1.5,M2,M2.5,M3,M4,M5,M6,M8,M10 |

|||

|

Precision |

DIN6,DIN7,DIN8,DIN9 |

|||

|

Surface treatment |

Black oxide,zinc galvanize, heat treatment, |

|||

|

Material |

Carbon steel,stainless steel,brass,pom,nylon,plastic |

|||

|

Process method |

CNC machining, Turning, milling ,drilling, grinding,shaving,shaping,hobbing |

|||

|

Application |

Automotive Parts,Hareware Par,Construction,Machinery, |

|||

|

Standard |

ISO |

|||

Related products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide |

|---|---|

| Warranty: | 1.5 Years |

| Type: | Gear Rack |

| Application: | Excavator |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can metric gear racks be customized for specific machinery and equipment?

Yes, metric gear racks can be customized to meet the specific requirements of machinery and equipment. Here’s a detailed explanation of the customization options available for metric gear racks:

Metric gear racks offer versatility and flexibility in their design and can be customized in various ways to suit specific applications. Some of the customization options include:

1. Length and Dimension: Gear racks can be customized in terms of their length and overall dimensions. The length of the gear rack can be tailored to match the required stroke or travel distance of the linear motion system. Additionally, the height, width, and thickness of the gear rack can be adjusted to fit within the available space and meet the specific clearance requirements of the machinery or equipment.

2. Tooth Profile: The tooth profile of the gear rack can be customized to optimize its performance for specific applications. The tooth profile determines the engagement characteristics with the mating gears or pinions. Common tooth profiles include straight (rectangular), helical, and circular arc. The selection of the appropriate tooth profile depends on factors such as load distribution, noise reduction, and smoothness of operation.

3. Material Selection: Gear racks can be customized by selecting the appropriate material based on the application requirements. Different materials, such as steel alloys or other high-strength materials, can be chosen to enhance the gear rack’s load-carrying capacity, durability, and resistance to wear and corrosion. The material selection can be tailored to suit specific environmental conditions, such as high temperature or corrosive environments.

4. Mounting Options: Customization of gear racks can include the provision of specific mounting options. Gear racks can be designed with pre-drilled holes or slots to facilitate easy installation and integration into the machinery or equipment. Custom mounting options ensure proper alignment and secure attachment of the gear rack, enabling smooth and reliable operation.

5. Coatings and Surface Treatments: Gear racks can be customized with various coatings and surface treatments to enhance their performance and longevity. For example, coatings like zinc plating or black oxide can provide corrosion resistance, while surface treatments such as grinding or polishing can improve the gear rack’s surface finish and reduce friction. Custom coatings and treatments can be applied based on the specific environmental and operational requirements of the application.

6. Special Features: Depending on the machinery or equipment’s unique needs, gear racks can be customized with special features or modifications. This may include adding additional features like sensor mounting brackets, position indicators, or integrated lubrication systems. Customized features ensure seamless integration and enhance the overall functionality of the gear rack within the specific application.

It is important to note that the extent of customization options may vary depending on the manufacturer and specific gear rack supplier. Collaborating with experienced gear rack manufacturers or suppliers is crucial to ensure that the customization requirements are met effectively.

In summary, metric gear racks can be customized for specific machinery and equipment by adjusting their length and dimensions, selecting the appropriate tooth profile and material, providing custom mounting options, applying coatings and surface treatments, and incorporating special features. Customized gear racks enable optimal integration and performance within the specific application, enhancing the overall efficiency and functionality of the machinery or equipment.

How do metric gear racks fit into the design of material handling equipment?

Metric gear racks play a crucial role in the design of material handling equipment, contributing to efficient and precise movement of goods. Here’s a detailed explanation of how metric gear racks fit into the design of material handling equipment:

1. Linear Motion Control: Material handling equipment often requires linear motion control to transport goods from one location to another. Metric gear racks, when combined with compatible mating gears and a motorized system, provide a reliable method for converting rotary motion into linear motion. Gear racks are integrated into the design of material handling equipment to create linear actuation systems that can move loads along a fixed path with high precision. By incorporating gear racks, material handling equipment can achieve smooth and controlled linear movement, enabling precise positioning and efficient transportation of goods.

2. Load Capacity: Material handling equipment is designed to handle various types and sizes of loads, ranging from small packages to heavy objects. Metric gear racks are engineered to withstand high loads, making them suitable for material handling applications. The design and construction of gear racks ensure efficient power transmission and load distribution along the rack’s length. This enables material handling equipment to lift, carry, and transport loads with stability and reliability. Gear racks with higher load capacities can be selected based on the specific requirements of the material handling equipment, ensuring safe and efficient operation.

3. Positioning and Indexing: Accurate positioning and indexing of goods are essential in material handling applications. Metric gear racks facilitate precise positioning by converting rotary motion into linear motion with a high degree of accuracy. By incorporating gear racks into the design of material handling equipment, such as conveyors or automated storage systems, goods can be moved to predetermined locations or indexed with precision. This allows for efficient sorting, distribution, and storage of goods in warehouses, manufacturing facilities, and logistics centers.

4. Conveyor Systems: Gear racks are commonly used in conveyor systems, which are an integral part of material handling equipment. In conveyor applications, gear racks are typically mounted on the frame of the conveyor, while the mating gears are connected to the conveyor belt or chain. The rotational motion of the motor is transferred to the gear rack system, resulting in linear movement of the conveyor belt or chain. This allows material handling equipment to transport goods smoothly and continuously along the conveyor path, enabling efficient material flow and handling operations.

5. Automated Guided Vehicles (AGVs): AGVs are autonomous vehicles used for material handling tasks in warehouses and industrial settings. Metric gear racks are often incorporated into the design of AGVs to enable precise linear motion control. The gear rack systems, combined with motorized drives and control systems, allow AGVs to navigate predefined paths accurately. Gear racks provide the necessary guidance and positioning control, ensuring that AGVs can transport goods safely and efficiently within the facility.

6. Lifting and Positioning Systems: Material handling equipment frequently requires lifting and positioning capabilities to handle goods at different heights and levels. Metric gear racks are utilized in lifting and positioning systems, such as scissor lifts or vertical conveyors, to achieve controlled vertical motion. The gear rack systems, when combined with suitable mating gears and actuators, enable material handling equipment to raise or lower loads with precision. This allows for efficient loading and unloading operations, as well as accurate positioning of goods at various heights.

7. Customizability: Metric gear racks offer flexibility and customization options to fit diverse material handling equipment designs. They are available in various sizes, modules, and materials, allowing engineers to select gear racks that align with the specific requirements of the equipment. Customizable features include tooth profile design, load capacity, and dimensional specifications. This flexibility enables the optimization of gear rack selection based on factors such as load, speed, precision, and environmental conditions, ensuring optimal performance in material handling applications.

8. Reliability and Durability: Material handling equipment operates in demanding environments and undergoes continuous use. Metric gear racks are designed to offer high reliability and durability, ensuring long service life and minimal downtime. The use of high-quality materials, precision manufacturing processes, and proper lubrication contribute to the gear racks’ ability to withstand heavy loads, repetitive motion, and challenging operating conditions. This reliability and durability make gear racks a suitable choice for material handling equipment, ensuring consistent and efficient movement of goods.

In summary, metric gear racks are integral to the design of material handling equipment, enabling efficient and precise movement of goods. By providing linear motion control, handling high loads, facilitating accurate positioning and indexing, and offering customization options, gear racks contribute to the functionality and performance of material handling systems. Whether used in conveyor systems, AGVs, lifting and positioning systems, or other material handling applications, metric“`html

How do metric gear racks fit into the design of material handling equipment?

Metric gear racks play a crucial role in the design of material handling equipment, contributing to efficient and precise movement of goods. Here’s a detailed explanation of how metric gear racks fit into the design of material handling equipment:

1. Linear Motion Control: Material handling equipment often requires linear motion control to transport goods from one location to another. Metric gear racks, when combined with compatible mating gears and a motorized system, provide a reliable method for converting rotary motion into linear motion. Gear racks are integrated into the design of material handling equipment to create linear actuation systems that can move loads along a fixed path with high precision. By incorporating gear racks, material handling equipment can achieve smooth and controlled linear movement, enabling precise positioning and efficient transportation of goods.

2. Load Capacity: Material handling equipment is designed to handle various types and sizes of loads, ranging from small packages to heavy objects. Metric gear racks are engineered to withstand high loads, making them suitable for material handling applications. The design and construction of gear racks ensure efficient power transmission and load distribution along the rack’s length. This enables material handling equipment to lift, carry, and transport loads with stability and reliability. Gear racks with higher load capacities can be selected based on the specific requirements of the material handling equipment, ensuring safe and efficient operation.

3. Positioning and Indexing: Accurate positioning and indexing of goods are essential in material handling applications. Metric gear racks facilitate precise positioning by converting rotary motion into linear motion with a high degree of accuracy. By incorporating gear racks into the design of material handling equipment, such as conveyors or automated storage systems, goods can be moved to predetermined locations or indexed with precision. This allows for efficient sorting, distribution, and storage of goods in warehouses, manufacturing facilities, and logistics centers.

4. Conveyor Systems: Gear racks are commonly used in conveyor systems, which are an integral part of material handling equipment. In conveyor applications, gear racks are typically mounted on the frame of the conveyor, while the mating gears are connected to the conveyor belt or chain. The rotational motion of the motor is transferred to the gear rack system, resulting in linear movement of the conveyor belt or chain. This allows material handling equipment to transport goods smoothly and continuously along the conveyor path, enabling efficient material flow and handling operations.

5. Automated Guided Vehicles (AGVs): AGVs are autonomous vehicles used for material handling tasks in warehouses and industrial settings. Metric gear racks are often incorporated into the design of AGVs to enable precise linear motion control. The gear rack systems, combined with motorized drives and control systems, allow AGVs to navigate predefined paths accurately. Gear racks provide the necessary guidance and positioning control, ensuring that AGVs can transport goods safely and efficiently within the facility.

6. Lifting and Positioning Systems: Material handling equipment frequently requires lifting and positioning capabilities to handle goods at different heights and levels. Metric gear racks are utilized in lifting and positioning systems, such as scissor lifts or vertical conveyors, to achieve controlled vertical motion. The gear rack systems, when combined with suitable mating gears and actuators, enable material handling equipment to raise or lower loads with precision. This allows for efficient loading and unloading operations, as well as accurate positioning of goods at various heights.

7. Customizability: Metric gear racks offer flexibility and customization options to fit diverse material handling equipment designs. They are available in various sizes, modules, and materials, allowing engineers to select gear racks that align with the specific requirements of the equipment. Customizable features include tooth profile design, load capacity, and dimensional specifications. This flexibility enables the optimization of gear rack selection based on factors such as load, speed, precision, and environmental conditions, ensuring optimal performance in material handling applications.

8. Reliability and Durability: Material handling equipment operates in demanding environments and undergoes continuous use. Metric gear racks are designed to offer high reliability and durability, ensuring long service life and minimal downtime. The use of high-quality materials, precision manufacturing processes, and proper lubrication contribute to the gear racks’ ability to withstand heavy loads, repetitive motion, and challenging operating conditions. This reliability and durability make gear racks a suitable choice for material handling equipment, ensuring consistent and efficient movement of goods.

In summary, metric gear racks are integral to the design of material handling equipment, enabling efficient and precise movement of goods. By providing linear motion control, handling high loads, facilitating accurate positioning and indexing, and offering customization options, gear racks contribute to the functionality and performance of material handling systems. Whether used in conveyor systems, AGVs, lifting and positioning systems, or other material handling.

What are the primary components and design features of a metric gear rack?

A metric gear rack consists of several primary components and incorporates specific design features to ensure its functionality and compatibility within gear systems. Here’s a detailed explanation of the primary components and design features of a metric gear rack:

1. Base Material: A metric gear rack is typically made from a sturdy and durable material, such as alloy steel, stainless steel, or engineering plastics. The selection of the base material depends on factors like the application requirements, load capacity, and environmental conditions. The base material should possess sufficient strength, wear resistance, and dimensional stability to withstand the forces and wear associated with gear engagement.

2. Tooth Profile: Metric gear racks feature a straight-sided tooth profile known as the involute profile. The involute shape allows for smooth and efficient engagement with mating gears or pinions. The tooth profile is designed based on the module system, where the module represents the size of the gear teeth. The module determines the tooth dimensions, including tooth height, tooth width, and tooth spacing, ensuring compatibility and proper meshing with mating gears or pinions.

3. Module Size: The module size is a critical design feature of a metric gear rack. It represents the size of the gear teeth and is defined as the ratio of the reference diameter to the number of teeth. The module size determines the tooth dimensions, such as the tooth height, tooth width, and tooth spacing. It plays a vital role in ensuring the proper engagement and meshing of the gear rack with mating gears or pinions, as well as determining the pitch of the gear rack.

4. Teeth: The primary feature of a metric gear rack is its teeth, which are evenly spaced along the length of the rack. The teeth engage with the mating gear or pinion to convert rotary motion into linear motion or vice versa. The teeth are precisely machined to ensure accurate tooth profiles and tight tolerances, allowing for smooth and efficient meshing with the mating gear or pinion. The tooth geometry and spacing are designed to minimize backlash and ensure precise positioning control.

5. Mounting Holes: Metric gear racks often include mounting holes along their length. These holes allow for easy attachment and secure mounting of the gear rack to the machinery or equipment. The mounting holes are strategically placed to ensure proper alignment and stability of the gear rack during operation. They facilitate the integration of the gear rack into the overall mechanical system and enable precise positioning and alignment of the rack within the machinery.

6. Surface Treatment: To enhance durability and corrosion resistance, metric gear racks may undergo surface treatments. Common surface treatments include heat treatment, such as carburizing or induction hardening, to increase hardness and wear resistance. Additionally, gear racks may undergo coating processes like nitriding or coating with materials like black oxide or zinc plating to provide additional protection against wear, friction, and corrosion.

7. Standardization: Metric gear racks are designed to conform to specific standards, ensuring compatibility and interchangeability with mating gears or pinions. Common standards include DIN (Deutsches Institut für Normung) and ISO (International Organization for Standardization) standards, which define the tooth profiles, dimensions, and tolerances of metric gear racks. Standardization allows for easy integration and replacement of gear rack components from different manufacturers.

These primary components and design features of a metric gear rack are carefully considered to ensure proper functionality, compatibility, and reliability within gear systems. The materials, tooth profile, module size, teeth design, mounting holes, surface treatment, and adherence to standards collectively contribute to the performance and longevity of metric gear racks in various machinery and mechanical applications.

editor by Dream 2024-05-03

China Standard China Factory High Precision Customized Rack for Heavy Duty Sliding Gate Plastic Gear spiral bevel gear

Product Description

China Factory High Precision Customized Rack for Heavy Duty Sliding Gate Plastic Gear

Detailed Photos

Company Profile

HangZhou NEWSCREW FASTENER CO., LTD.

NEWSCREW FASTENER was founded in 2008. We own 2 factories located in ZHangZhoug and ZheJiang Province, which have superior geographical advantages. With a total investment of 3 million US dollars, we have 315 employees and cover more than 25,000 square meters.

As a key fastener enterprise, we are a member of the National Fastener Standardization Technical Committee. We have strong technical force and advanced equipments like multi-station cold heading machines, fastener manufacturing machines, raw material annealing furnaces, heat treatment furnaces, electro-galvanizing production lines, blackening production lines, etc. We also have complete quality testing system and passed ISO9001 quality management system certification.

We export our products to more than 40 countries, such as United States, Europe, South America, Africa, the Middle East and so on. Our products include threaded rods, bolts, nuts, various screws, washers, anchors etc., which are used in machinery, vehicles, shipbuilding, railway, construction, instrumentation and other industries. Product standards include German standard, Australian standard, American standard, Japanese standard and national standard.

Workshop for bolt, screw, threaded rod, nut, etc

Our Exhibition

Canton Fair – Fastener Fair Stuttgart – Fastener Fair Mexico

Package for screw ,bolt, threaded rod, nut etc

| Main Products: Carbon steel and Stainless steel |

| Rod : Threaded rod, stud bolt ect |

| BOLT : Hex bolt , Carriage bolt, Hex flange head bolt, achor bolt ect |

| Nut : Hex nut, Hex nylon nut, CHINAMFG nut, cap nut, T-Nut, Square nut, Rivet nut, Hex coupling nut etc |

| Screw : Drywall Screw, Chipboard screw, Wood screw, Self tapping screw, Machine screw, roofing screw, Self drilling screw Concrete screw, Confirmat screw, Decking screw etc. |

| Washer : Flat washer, Spring washer, Lock washer, Plain washer ect |

| Anchor: Wedge anchor, Drop in anchor, Ceiling anchor, Sleeve anchor, Hammer drive anchor etc. |

| Rivet: Blind rivet |

| Rigging: Turnbukles, D Shackle,Wire Rope Thimbles, Wire Rope Clip, Quick Link,Spring Snap Hook, Eye Bolt, Eye Nut, etc. |

| No-standard Products: Auto Parts, Photovoltaic products, Customized Fasteners and so on |

Certificates:

ISO 9001

3.1B cerfificate

SGS report

FAQ.

Q: Are you manufacturer or trading company ?

A: We produce threaded rods for more than 14 years, We owned more than 76 sets of producing equipments.

Q: What’s your sample policy ?

A: Our sample is free

Q: What’s your MOQ ?

A: 200 kgs per size

Q: What’s your payment term:

A: TT, LC, DP

Q:How is your inspection process ?

A:We have good QC inspection tear and full set of inspect equipment, we can give quality certificates.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum |

|---|---|

| Type: | All Kinds of Head |

| Connection: | Common Bolt |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations should be kept in mind when working with metric gear racks?

Working with metric gear racks requires careful attention to safety to prevent accidents and ensure the well-being of individuals involved. Here’s a detailed explanation of the safety considerations that should be kept in mind:

1. Protective Measures: When working with gear racks, it is essential to use appropriate personal protective equipment (PPE) such as safety glasses, gloves, and protective clothing. PPE helps protect against potential hazards such as sharp edges, flying debris, or accidental contact with moving parts. Safety shoes with slip-resistant soles should be worn to prevent slips and falls in the work area.

2. Lockout/Tagout: Before performing any maintenance or repair tasks on machinery or equipment involving gear racks, it is crucial to follow lockout/tagout procedures. Lockout/tagout involves isolating the power source and securing it with a lock or tag to prevent unexpected startup or release of stored energy. This procedure ensures that the gear rack and associated machinery are in a safe state during maintenance or repair activities.

3. Proper Training: Adequate training is vital for individuals working with gear racks. Operators, maintenance personnel, and other involved individuals should receive training on the safe handling, operation, and maintenance of gear racks. Training should cover topics such as proper installation procedures, safe working distances, emergency shutdown protocols, and the use of safety devices. Well-trained personnel are more aware of potential risks and can take appropriate precautions to prevent accidents.

4. Clearance and Workspace: It is important to ensure sufficient clearance around the gear rack system for safe operation and maintenance. Adequate workspace allows personnel to perform tasks comfortably without being at risk of getting trapped or injured. Machinery or equipment incorporating gear racks should be properly designed and arranged to provide safe access for maintenance and inspection activities.

5. Regular Inspections: Scheduled inspections of gear racks are essential to identify any signs of wear, damage, or misalignment. Regular inspections help detect potential safety hazards before they escalate into more significant issues. Any worn or damaged components should be promptly replaced to ensure the safe operation of the gear rack system. Lubrication levels should also be checked and maintained as per manufacturer recommendations to prevent excessive friction or overheating.

6. Safe Loading and Operation: When loading objects onto gear racks, it is important to adhere to the recommended load limits specified by the manufacturer. Overloading the gear rack can lead to excessive stress, premature wear, and potential failure. Additionally, the gear rack should be operated within its designed speed limits to maintain safe and reliable performance. Sudden changes in speed or excessive acceleration should be avoided to prevent accidents or loss of control.

7. Emergency Stop and Warning Systems: Gear rack systems should be equipped with emergency stop buttons or switches that can quickly halt the operation in case of an emergency. Clear warning signs and labels should be placed near the gear rack system to alert personnel about potential hazards and safety precautions. Properly functioning emergency stop and warning systems contribute to a safer working environment.

8. Proper Handling and Lifting Techniques: When handling gear racks or related components, proper lifting techniques should be employed to prevent strains or injuries. The use of lifting equipment, such as cranes or hoists, may be necessary for heavier gear rack assemblies. Personnel should be trained in safe lifting practices and use appropriate lifting aids to avoid accidents and minimize physical strain.

9. Documentation and Manuals: Manufacturers provide documentation and manuals that contain important safety information specific to their gear rack products. It is crucial to read and understand these materials, including safety guidelines, recommended maintenance procedures, and emergency procedures. Following the manufacturer’s instructions ensures compliance with safety requirements and helps prevent accidents.

10. Risk Assessment: Conducting a thorough risk assessment of the gear rack system and its associated machinery is essential. Identifying potential hazards, evaluating risks, and implementing appropriate control measures are crucial steps in ensuring the safety of personnel working with gear racks. Risk assessments should be periodically reviewed and updated as necessary to address any changes in the working environment or operational conditions.

It is important to note that the above safety considerations are general guidelines, and specific safety requirements may vary depending on the application, industry, and local regulations. Consulting with safety professionals and following industry best practices is recommended to ensure comprehensive safety measures are in place when working with metric gear racks.

In summary, maintaining a safe working environment when working with metric gear racks involves implementing protective measures, following lockout/tagout procedures, providing proper training, ensuring adequate clearance and workspace, conducting regular inspections, loading and operating within safe limits, utilizing emergency stop andwarning systems, using proper handling and lifting techniques, familiarizing oneself with documentation and manuals, and conducting a thorough risk assessment. By prioritizing safety considerations, individuals can minimize the risk of accidents and create a safer working environment when working with metric gear racks.

Can metric gear racks be used in automotive applications, and if so, where?

Metric gear racks can indeed be used in various automotive applications, contributing to the functionality and performance of automotive systems. Here’s a detailed explanation of how metric gear racks can be utilized in automotive applications:

1. Power Steering Systems: Metric gear racks are commonly employed in power steering systems to assist the driver in steering the vehicle. In power steering applications, a gear rack is connected to the steering column, while a pinion gear meshes with the gear rack and is driven by a power steering pump. As the driver turns the steering wheel, the rotational motion is converted into linear motion through the gear rack system, allowing for easier and more precise steering control. Metric gear racks in power steering systems enable smooth and responsive steering, enhancing the overall driving experience.

2. Transmission Systems: Gear racks can be utilized in automotive transmission systems, particularly in the design of manual transmissions. In manual transmissions, gear racks are employed in the shifting mechanism to engage or disengage different gears. The gear rack, along with a shift fork and synchronizer, enables the driver to select the desired gear by moving the gear rack linearly. This action engages the corresponding gear on the transmission’s output shaft, allowing for gear changes and power transmission. Metric gear racks in transmission systems contribute to the precise and efficient shifting of gears in manual transmissions.

3. Seat Adjustment Mechanisms: Metric gear racks are employed in seat adjustment mechanisms to enable the positioning and adjustment of automotive seats. Gear racks, along with a motorized or manually operated mechanism, allow for the linear movement of the seat along different axes, such as forward/backward, up/down, and recline. By incorporating gear racks, automotive seats can be adjusted to accommodate the preferences and comfort of the driver and passengers. The use of metric gear racks in seat adjustment mechanisms provides smooth and precise seat positioning for an enhanced seating experience.

4. Convertible Top Mechanisms: In convertible vehicles, metric gear racks can be utilized in the mechanisms responsible for raising and lowering the convertible top. Gear racks, along with compatible mating gears and a motorized system, enable the linear motion required to operate the convertible top mechanism. By incorporating gear racks, automotive convertibles can smoothly and reliably raise or lower the top, allowing for quick and convenient transition between open-air and closed-roof driving. Metric gear racks in convertible top mechanisms contribute to seamless convertible top operation and enhance the overall driving experience.

5. Sunroof Mechanisms: Metric gear racks can be employed in automotive sunroof mechanisms to facilitate the opening and closing of sunroof panels. Gear racks, along with suitable gears and a motorized or manually operated system, enable the linear motion required for sunroof operation. By incorporating gear racks, automotive sunroofs can be easily opened or closed, providing ventilation, natural light, and an open-air driving experience when desired. Metric gear racks in sunroof mechanisms contribute to smooth and reliable sunroof operation.

6. Other Automotive Applications: Metric gear racks can also be utilized in various other automotive applications, including throttle control systems, HVAC (heating, ventilation, and air conditioning) systems, and adjustable pedals. In these applications, gear racks enable linear motion control, precise positioning, and adjustment of automotive components, enhancing vehicle performance, comfort, and convenience.

In summary, metric gear racks find application in several automotive systems and mechanisms. From power steering and transmission systems to seat adjustments, convertible tops, sunroofs, and other automotive applications, gear racks contribute to the precise and reliable operation of various automotive functions. By providing linear motion control, gear racks enhance the functionality, comfort, and overall driving experience in automotive applications.

“`html

Can metric gear racks be used in automotive applications, and if so, where?

Metric gear racks can indeed be used in various automotive applications, contributing to the functionality and performance of automotive systems. Here’s a detailed explanation of how metric gear racks can be utilized in automotive applications:

1. Power Steering Systems: Metric gear racks are commonly employed in power steering systems to assist the driver in steering the vehicle. In power steering applications, a gear rack is connected to the steering column, while a pinion gear meshes with the gear rack and is driven by a power steering pump. As the driver turns the steering wheel, the rotational motion is converted into linear motion through the gear rack system, allowing for easier and more precise steering control. Metric gear racks in power steering systems enable smooth and responsive steering, enhancing the overall driving experience.

2. Transmission Systems: Gear racks can be utilized in automotive transmission systems, particularly in the design of manual transmissions. In manual transmissions,“`html

Can metric gear racks be used in automotive applications, and if so, where?

Metric gear racks can indeed be used in various automotive applications, contributing to the functionality and performance of automotive systems. Here’s a detailed explanation of how metric gear racks can be utilized in automotive applications:

1. Power Steering Systems: Metric gear racks are commonly employed in power steering systems to assist the driver in steering the vehicle. In power steering applications, a gear rack is connected to the steering column, while a pinion gear meshes with the gear rack and is driven by a power steering pump. As the driver turns the steering wheel, the rotational motion is converted into linear motion through the gear rack system, allowing for easier and more precise steering control. Metric gear racks in power steering systems enable smooth and responsive steering, enhancing the overall driving experience.

2. Transmission Systems: Gear racks can be utilized in automotive transmission systems, particularly in the design of manual transmissions. In manual transmissions, gear racks are employed in the shifting mechanism to engage or disengage different gears. The gear rack, along with a shift fork and synchronizer, enables the driver to select the desired gear by moving the gear rack linearly. This action engages the corresponding gear on the transmission’s output shaft, allowing for gear changes and power transmission. Metric gear racks in transmission systems contribute to the precise and efficient shifting of gears in manual transmissions.

3. Seat Adjustment Mechanisms: Metric gear racks are employed in seat adjustment mechanisms to enable the positioning and adjustment of automotive seats. Gear racks, along with a motorized or manually operated mechanism, allow for the linear movement of the seat along different axes, such as forward/backward, up/down, and recline. By incorporating gear racks, automotive seats can be adjusted to accommodate the preferences and comfort of the driver and passengers. The use of metric gear racks in seat adjustment mechanisms provides smooth and precise seat positioning for an enhanced seating experience.

4. Convertible Top Mechanisms: In convertible vehicles, metric gear racks can be utilized in the mechanisms responsible for raising and lowering the convertible top. Gear racks, along with compatible mating gears and a motorized system, enable the linear motion required to operate the convertible top mechanism. By incorporating gear racks, automotive convertibles can smoothly and reliably raise or lower the top, allowing for quick and convenient transition between open-air and closed-roof driving. Metric gear racks in convertible top mechanisms contribute to seamless convertible top operation and enhance the overall driving experience.

5. Sunroof Mechanisms: Metric gear racks can be employed in automotive sunroof mechanisms to facilitate the opening and closing of sunroof panels. Gear racks, along with suitable gears and a motorized or manually operated system, enable the linear motion required for sunroof operation. By incorporating gear racks, automotive sunroofs can be easily opened or closed, providing ventilation, natural light, and an open-air driving experience when desired. Metric gear racks in sunroof mechanisms contribute to smooth and reliable sunroof operation.

6. Other Automotive Applications: Metric gear racks can also be utilized in various other automotive applications, including throttle control systems, HVAC (heating, ventilation, and air conditioning) systems, and adjustable pedals. In these applications, gear racks enable linear motion control, precise positioning, and adjustment of automotive components, enhancing vehicle performance, comfort, and convenience.

In summary, metric gear racks find application in several automotive systems and mechanisms. From power steering and transmission systems to seat adjustments, convertible tops, sunroofs, and other automotive applications, gear racks contribute to the precise and reliable operation of various automotive functions. By providing linear motion control, gear racks enhance the functionality, comfort, and overall driving experience in automotive applications.

How do metric gear racks handle variations in load capacity and speed?

Metric gear racks are designed to handle variations in load capacity and speed effectively. Here’s a detailed explanation of how they address these variations:

Metric gear racks accommodate variations in load capacity and speed through the following mechanisms:

1. Selection of Gear Rack Material: The choice of material for the gear rack plays a crucial role in determining its load capacity and speed handling capabilities. Gear racks are typically made from high-strength materials like steel or other durable alloys. These materials offer excellent load-bearing capacity and can withstand high forces without deformation or failure. The selection of the appropriate material ensures that the gear rack can handle varying loads without compromising its structural integrity or performance.

2. Proper Gear Rack Sizing: The size and dimensions of the gear rack are selected based on the anticipated load and speed requirements of the application. Larger gear racks with more substantial cross-sectional dimensions and larger teeth are capable of handling higher loads. Smaller gear racks are suitable for lighter loads. Proper sizing ensures that the gear rack can withstand the expected load capacity while maintaining the required speed and accuracy. Engineering calculations and analysis are often performed to determine the optimal size and dimensions of the gear rack for a given application.

3. Load Distribution: Gear racks distribute the applied load along their length, which helps in handling variations in load capacity. The toothed engagement between the gear rack and mating gears or pinions ensures that the load is evenly distributed across the entire length of the rack. This load distribution mechanism prevents localized stress concentration and minimizes the risk of failure or deformation in specific areas. By distributing the load, gear racks can handle variations in load capacity and maintain consistent performance throughout their length.

4. Lubrication and Maintenance: Proper lubrication and maintenance of gear racks are essential for ensuring their optimal performance under varying load and speed conditions. Lubrication helps reduce friction and wear between the gear rack teeth and the mating gears or pinions. Adequate lubrication minimizes heat generation, reduces the risk of premature wear, and maintains the overall efficiency of the gear system. Regular inspection and maintenance of gear racks, including cleaning, lubrication, and replacement of worn components, help extend their service life and ensure reliable operation under varying load and speed requirements.

5. System Design and Integration: The overall design and integration of the gear rack system play a vital role in handling variations in load capacity and speed. Proper system design includes selecting compatible gears or pinions, ensuring proper alignment, and considering factors such as torque requirements, backlash, and speed ratios. By designing the gear rack system appropriately, engineers can optimize its performance and ensure that it can handle variations in load capacity and speed effectively.

It is important to note that while gear racks can handle variations in load capacity and speed, there are limits to their capabilities. Exceeding the recommended load capacity or operating at excessively high speeds can lead to premature wear, increased backlash, reduced accuracy, and potential system failure. Therefore, it is crucial to carefully consider the specific load and speed requirements of the application and select gear racks that are suitable for the anticipated operating conditions.

In summary, metric gear racks handle variations in load capacity and speed through the selection of appropriate materials, proper sizing, load distribution, lubrication and maintenance, and thoughtful system design and integration. By considering these factors, gear racks can effectively handle varying load and speed requirements while maintaining accurate and reliable linear motion.

editor by Dream 2024-04-30

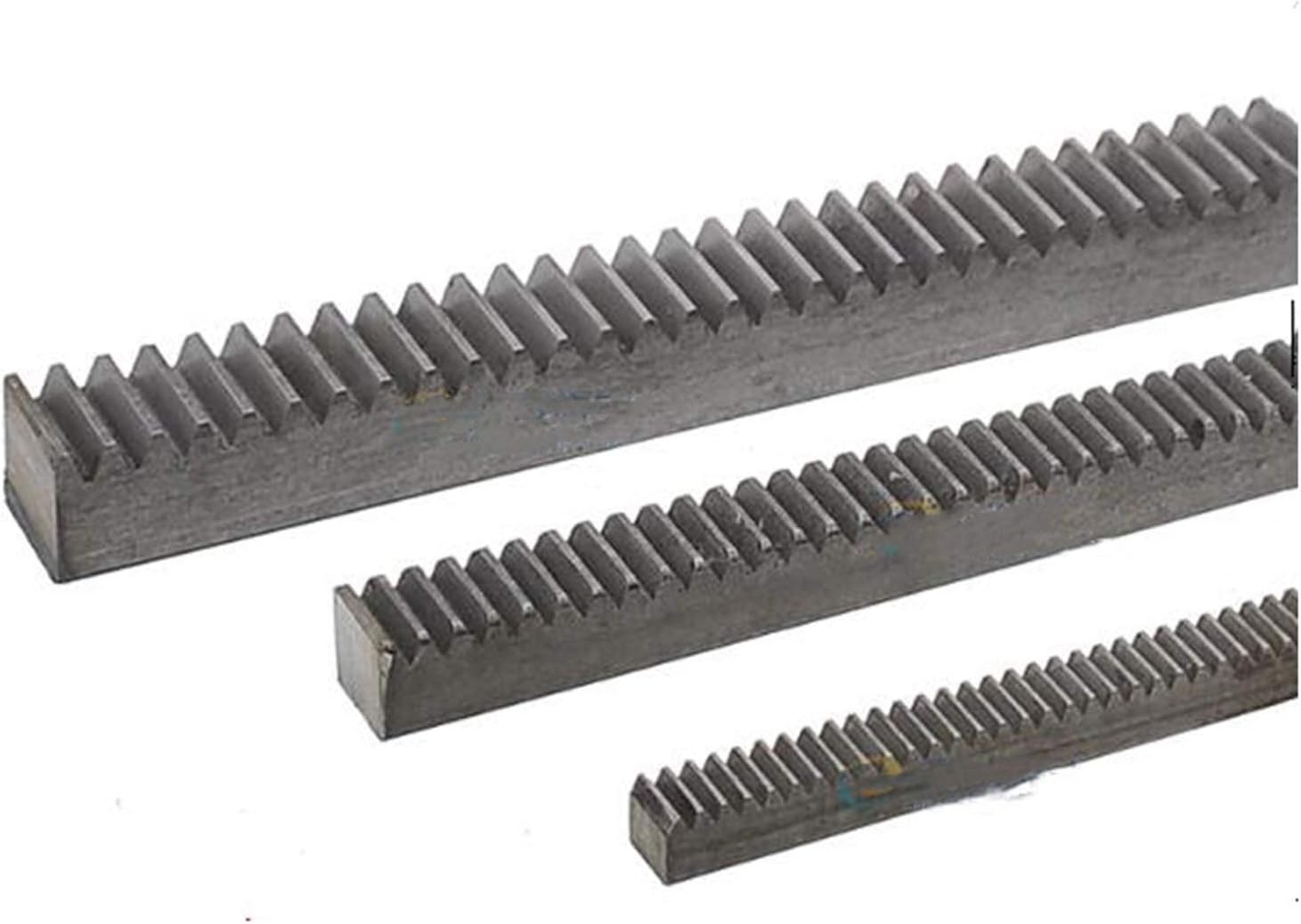

China supplier Mechanical Parts Rack and Pinion Gear Small Metal Stainless Steel Hard Tooth Surface Cutting Rack Gear Gear Rack for Woodworking Industry with high quality

Product Description

mechanical parts rack and pinion gear small metal stainless steel hard tooth surface cutting rack gear gear rack for Woodworking Industry

|

Product name |

Gear rack |

|||

|

Type |

Helical gear rack,spur gear rack,sliding gate gear rack |

|||

|

Module |

M1,M1.5,M2,M2.5,M3,M4,M5,M6,M8,M10 |

|||

|

Precision |

DIN6,DIN7,DIN8,DIN9 |

|||

|

Surface treatment |

Black oxide,zinc galvanize, heat treatment, |

|||

|

Material |

Carbon steel,stainless steel,brass,pom,nylon,plastic |

|||

|

Process method |

CNC machining, Turning, milling ,drilling, grinding,shaving,shaping,hobbing |

|||

|

Application |

Automotive Parts,Hareware Par,Construction,Machinery, |

|||

|

Standard |

ISO |

|||

Related products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide |

|---|---|

| Warranty: | 1.5 Years |

| Type: | Gear Rack |

| Application: | Excavator |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What safety considerations should be kept in mind when working with metric gear racks?