Product Description

Product Description:

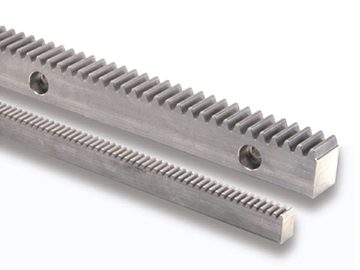

Factory sale gear rack pinion for automatic sliding gate

Mighty can supply standard gear racks for automatic sliding gate, mainly including:

M4 8*30*1005 mm M4 10*30*1005 mm M4 12*30*1998 mm

Surely the sizes could be customized for you according to your request.

OEM order is accepted!

About Steel Gear racks:

Our steel Gear Racks are exported in big quantity to Europe,America etc.Our gear racks producedby,CNC machines.Our steel gear racks,cnc gear racks,gear racks M1,racks and pinion steering gears are exported in big quantity to Europe,America,Australia,Brazil,etc.There are standard gear racks available and also special gear racks as per your drawings or sampls.Standards or special gear racks produced by CNC machines.

Note of steel gear racks:

1. Material: Carbon steel, stainless steel, aluminium alloy, plastic, brass etc.

2. Module: M1, M1.5, M2, M3, M4, M5, M6, M7, M8 etc.

3. The pressure angle: 20°.

4. Surface treatment: Zinc-plated, Nickle-plated, Black-Oxide, Carburizing, Hardening and tempering,

nitriding, high frequency treatment etc.

5. Production Machines: Gear shaper, hobbing machine, CNC lathe, milling machine, drilling machine,

grinder etc.

6. Heat treatment carburizing and quenching.

7. Surface disposal: forced shot-peening.

Data sheet

| Specification LxWxH(mm) | Material | Module |

| 1005x8x30 |

A3 STEEL C45 STEEL Stainless Steel |

4 |

| 1005x9x30 | 4 | |

| 1005x10x30 | 4 | |

| 1005x11x30 | 4 | |

| 1005x12x30 | 4 | |

| 1002x12x30 | 4 | |

| 1004x12x30 | 4 | |

| 1005x15x30 | 4 | |

| 1005x20x20 | 4 | |

| 1005x22x22 | 4 | |

| 1005x25x25 | 4 | |

| 1005x30x30 | 6 | |

| 1004x8x40 | 5 |

Use:

Our steel gear rack, CNC gear racks, spur gear racks, stainless gear racks, special gear racks, aluminum gear racks, round gear racks, gear and racks, gear rack M4 gear racks, gears rack M1, racks and pinion steering gear are exported in big quantity to Europe, America, Australia, Brasil, South Africa, Russia etc.There is standard gear racks available and also special gear racks as per your drawing or samples. Standards or special gear racks produced by CNC machine.

Packaging & Shipping:

Packaging:

1. Commerial Packaging: Plastic bag + paper box+wooden case + wooden pallet.

2. According to clients’ requirements.

Shipping:

1. Express Delivery: DHL,TNT,UPS,Fedex,EMS,ARAMEX, 4-7working days to arrive if smooth

2. By Air

3. By Sea

Our Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling: including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling,

Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack.

8. Other customized Machining Parts according to drawings (OEM) Forging, Casting, Stamping Parts.

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTOTY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Slidng Door |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Standard and Custom |

| Manufacturing Method: | Hobbing |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can metric gear racks be customized for specific machinery and equipment?

Yes, metric gear racks can be customized to meet the specific requirements of machinery and equipment. Here’s a detailed explanation of the customization options available for metric gear racks:

Metric gear racks offer versatility and flexibility in their design and can be customized in various ways to suit specific applications. Some of the customization options include:

1. Length and Dimension: Gear racks can be customized in terms of their length and overall dimensions. The length of the gear rack can be tailored to match the required stroke or travel distance of the linear motion system. Additionally, the height, width, and thickness of the gear rack can be adjusted to fit within the available space and meet the specific clearance requirements of the machinery or equipment.

2. Tooth Profile: The tooth profile of the gear rack can be customized to optimize its performance for specific applications. The tooth profile determines the engagement characteristics with the mating gears or pinions. Common tooth profiles include straight (rectangular), helical, and circular arc. The selection of the appropriate tooth profile depends on factors such as load distribution, noise reduction, and smoothness of operation.

3. Material Selection: Gear racks can be customized by selecting the appropriate material based on the application requirements. Different materials, such as steel alloys or other high-strength materials, can be chosen to enhance the gear rack’s load-carrying capacity, durability, and resistance to wear and corrosion. The material selection can be tailored to suit specific environmental conditions, such as high temperature or corrosive environments.

4. Mounting Options: Customization of gear racks can include the provision of specific mounting options. Gear racks can be designed with pre-drilled holes or slots to facilitate easy installation and integration into the machinery or equipment. Custom mounting options ensure proper alignment and secure attachment of the gear rack, enabling smooth and reliable operation.

5. Coatings and Surface Treatments: Gear racks can be customized with various coatings and surface treatments to enhance their performance and longevity. For example, coatings like zinc plating or black oxide can provide corrosion resistance, while surface treatments such as grinding or polishing can improve the gear rack’s surface finish and reduce friction. Custom coatings and treatments can be applied based on the specific environmental and operational requirements of the application.

6. Special Features: Depending on the machinery or equipment’s unique needs, gear racks can be customized with special features or modifications. This may include adding additional features like sensor mounting brackets, position indicators, or integrated lubrication systems. Customized features ensure seamless integration and enhance the overall functionality of the gear rack within the specific application.

It is important to note that the extent of customization options may vary depending on the manufacturer and specific gear rack supplier. Collaborating with experienced gear rack manufacturers or suppliers is crucial to ensure that the customization requirements are met effectively.

In summary, metric gear racks can be customized for specific machinery and equipment by adjusting their length and dimensions, selecting the appropriate tooth profile and material, providing custom mounting options, applying coatings and surface treatments, and incorporating special features. Customized gear racks enable optimal integration and performance within the specific application, enhancing the overall efficiency and functionality of the machinery or equipment.

Can metric gear racks be used for both rotary and linear motion?

Yes, metric gear racks can be used for both rotary and linear motion. Here’s a detailed explanation of how metric gear racks can be utilized for these types of motion:

1. Linear Motion: Gear racks are primarily designed to provide linear motion. A gear rack consists of straight teeth that are cut along one edge of a linear component. The teeth of the gear rack mesh with the teeth of a mating gear, typically a spur gear or a helical gear. As the mating gear rotates, it engages with the gear rack and translates the rotational motion into linear motion. This linear motion can be used in various applications, such as in machinery, automation systems, robotics, and conveyors, where linear movement is required.

2. Rotary Motion: While gear racks are primarily used for linear motion, they can also be adapted for rotary motion in specific scenarios. One common method is by using a pinion gear, which is a small gear with teeth that mesh with the gear rack. The pinion gear is mounted on a rotating shaft, and as it engages with the gear rack, it converts the linear motion of the rack into rotary motion of the shaft. This configuration is often used in applications where a linear actuator or a rack and pinion mechanism is required to transform linear motion into rotational motion or vice versa. Examples include steering systems in automobiles, CNC machines, or rack and pinion lifts.

It is important to note that while gear racks can be used for both rotary and linear motion, their primary purpose is to provide linear motion. Rotary motion is achieved by incorporating additional components, such as pinion gears or other types of gears, to convert the linear motion of the gear rack into rotational motion. The specific design and configuration depend on the application requirements and the desired motion transformation.

In summary, metric gear racks are versatile components that can be used for both linear and rotary motion. Their primary function is to provide linear motion when meshed with a mating gear. However, by incorporating pinion gears or other gears, the linear motion of the gear rack can be transformed into rotary motion. This flexibility allows engineers to utilize gear racks in a wide range of applications where both types of motion are required.

How do metric gear racks handle variations in load capacity and speed?

Metric gear racks are designed to handle variations in load capacity and speed effectively. Here’s a detailed explanation of how they address these variations:

Metric gear racks accommodate variations in load capacity and speed through the following mechanisms:

1. Selection of Gear Rack Material: The choice of material for the gear rack plays a crucial role in determining its load capacity and speed handling capabilities. Gear racks are typically made from high-strength materials like steel or other durable alloys. These materials offer excellent load-bearing capacity and can withstand high forces without deformation or failure. The selection of the appropriate material ensures that the gear rack can handle varying loads without compromising its structural integrity or performance.

2. Proper Gear Rack Sizing: The size and dimensions of the gear rack are selected based on the anticipated load and speed requirements of the application. Larger gear racks with more substantial cross-sectional dimensions and larger teeth are capable of handling higher loads. Smaller gear racks are suitable for lighter loads. Proper sizing ensures that the gear rack can withstand the expected load capacity while maintaining the required speed and accuracy. Engineering calculations and analysis are often performed to determine the optimal size and dimensions of the gear rack for a given application.

3. Load Distribution: Gear racks distribute the applied load along their length, which helps in handling variations in load capacity. The toothed engagement between the gear rack and mating gears or pinions ensures that the load is evenly distributed across the entire length of the rack. This load distribution mechanism prevents localized stress concentration and minimizes the risk of failure or deformation in specific areas. By distributing the load, gear racks can handle variations in load capacity and maintain consistent performance throughout their length.

4. Lubrication and Maintenance: Proper lubrication and maintenance of gear racks are essential for ensuring their optimal performance under varying load and speed conditions. Lubrication helps reduce friction and wear between the gear rack teeth and the mating gears or pinions. Adequate lubrication minimizes heat generation, reduces the risk of premature wear, and maintains the overall efficiency of the gear system. Regular inspection and maintenance of gear racks, including cleaning, lubrication, and replacement of worn components, help extend their service life and ensure reliable operation under varying load and speed requirements.

5. System Design and Integration: The overall design and integration of the gear rack system play a vital role in handling variations in load capacity and speed. Proper system design includes selecting compatible gears or pinions, ensuring proper alignment, and considering factors such as torque requirements, backlash, and speed ratios. By designing the gear rack system appropriately, engineers can optimize its performance and ensure that it can handle variations in load capacity and speed effectively.

It is important to note that while gear racks can handle variations in load capacity and speed, there are limits to their capabilities. Exceeding the recommended load capacity or operating at excessively high speeds can lead to premature wear, increased backlash, reduced accuracy, and potential system failure. Therefore, it is crucial to carefully consider the specific load and speed requirements of the application and select gear racks that are suitable for the anticipated operating conditions.

In summary, metric gear racks handle variations in load capacity and speed through the selection of appropriate materials, proper sizing, load distribution, lubrication and maintenance, and thoughtful system design and integration. By considering these factors, gear racks can effectively handle varying load and speed requirements while maintaining accurate and reliable linear motion.

editor by Dream 2024-04-26